RW3 Solid Water Standard Phantoms

for QA and Dosimetry

RW3 Solid Water Standard Phantoms replicate human soft tissue with remarkable accuracy and ensure reproducible results in every QA and dosimetry task. Their stable RW3 material enables precise calibration for photon and electron beam applications across clinics and OEM systems. They define the reference standard for validation, commissioning, and long-term dose verification in radiotherapy.

RW3 tissue-equivalent material

for precise, repeatable

dose measurements

Modular phantoms

for QA, commissioning

& end-to-end checks

MR-compatible

for RT laser alignment

& distortion control

CE/MDR & FDA

for global clinical use

Why Accuracy Matters in Radiotherapy QA

Precise dosimetry defines the safety and effectiveness of every treatment. Even minor deviations in calibration or beam verification can alter dose delivery and compromise patient outcomes. The following challenges show why QA and calibration phantoms are essential for accuracy and reproducibility.

Tissue Equivalence

Water equivalence is the foundation of every dosimetry process. Material inhomogeneity or poor attenuation matching causes systematic dose errors and limits comparability between QA setups.

Long-Term Stability

Repeated irradiation and handling can cause density drift or surface degradation/browning in inferior phantom materials. This affects measurement reproducibility across QA cycles and detectors.

Modularity and Flexibility

Different QA tasks require specific geometries. Without modular systems, users must rely on multiple phantoms or compromise detector alignment accuracy.

Compliance and Integration

Modern OEM systems and clinical environments demand materials and documentation compliant with CE/MDR and FDA standards. Missing conformity limits international deployment and OEM integration.

Advantages and Benefits

RW3 Solid Water Standard Phantoms address all these issues with reproducible, tissue-equivalent properties, long-term stability, and full regulatory readiness. Every unit undergoes CT scanning to verify homogeneity before shipment, ensuring precise calibration and QA consistency across photon and electron applications.

- Verified tissue equivalence with 1.045 g/cm³ density

- Long-term radiation stability for repeated QA and calibration

- Modular system design for routine, commissioning, and end-to-end QA

- Compatible with ion chambers, diodes, TLDs, EPIDs, and films

- CE/MDR compliant and FDA-ready documentation for OEM use

- Custom adapter options for detectors and OEM workflows

How You Benefit

Reproducible Dosimetry

RW3’s consistent material composition guarantees identical dose readings across detectors and setups - essential for QA comparisons and system calibration.

OEM Integration

RW3 phantoms are available with custom adapters, inserts, and anthropomorphic shapes, enabling seamless integration into OEM QA and commissioning systems.

Long-Term Durability

Mechanically stable and resistant to radiation aging, RW3 maintains its properties even after years of use in clinical and research environments.

Our Comprehensive QA Solutions

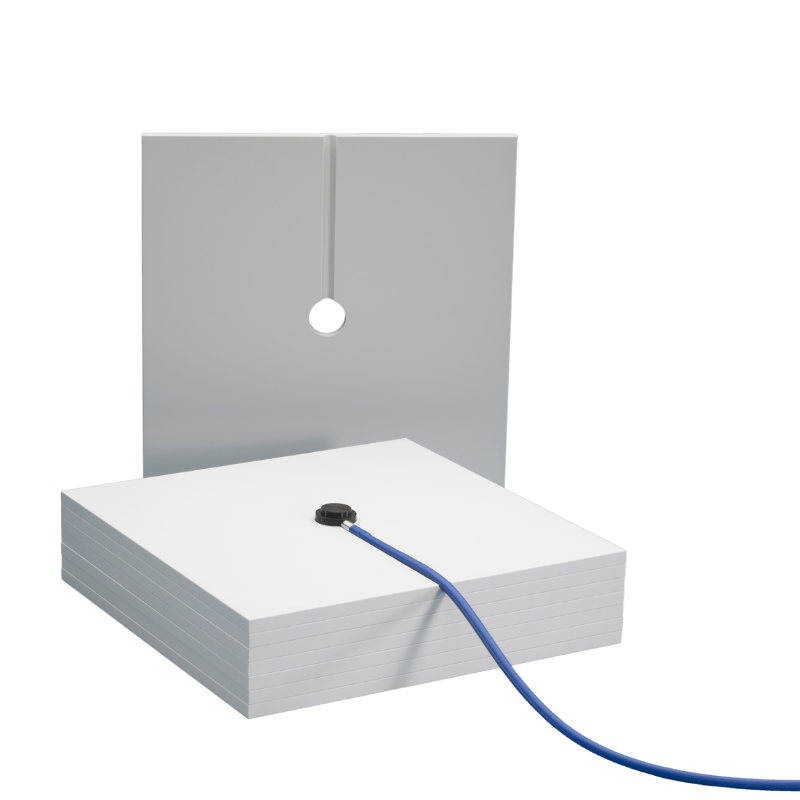

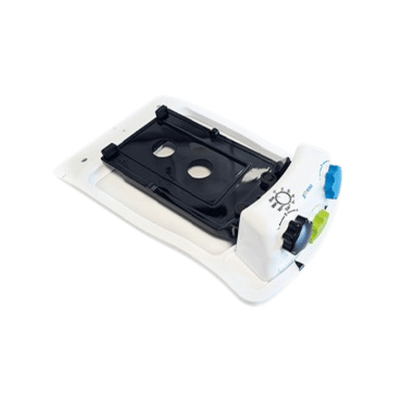

EASY SLAB Phantom optimized for Routine Dosimetry

EASY SLAB is a modular phantom system for frequent QA tasks in radiotherapy. Built from homogeneous RW3 material, it provides reproducible measurements for absolute dose checks and dose distribution verification. With dedicated adapter plates, detectors can be positioned with sub-millimeter precision. OEMs and clinics use EASY SLAB to streamline routine QA with maximum flexibility. gKteso builds hundreds of units every year. Various slab sizes (such as 30cm x 30cm and 40cm x 40cm) and thicknesses (1mm, 2mm, 5mm, 10mm, 20mm, 60mm) are available.

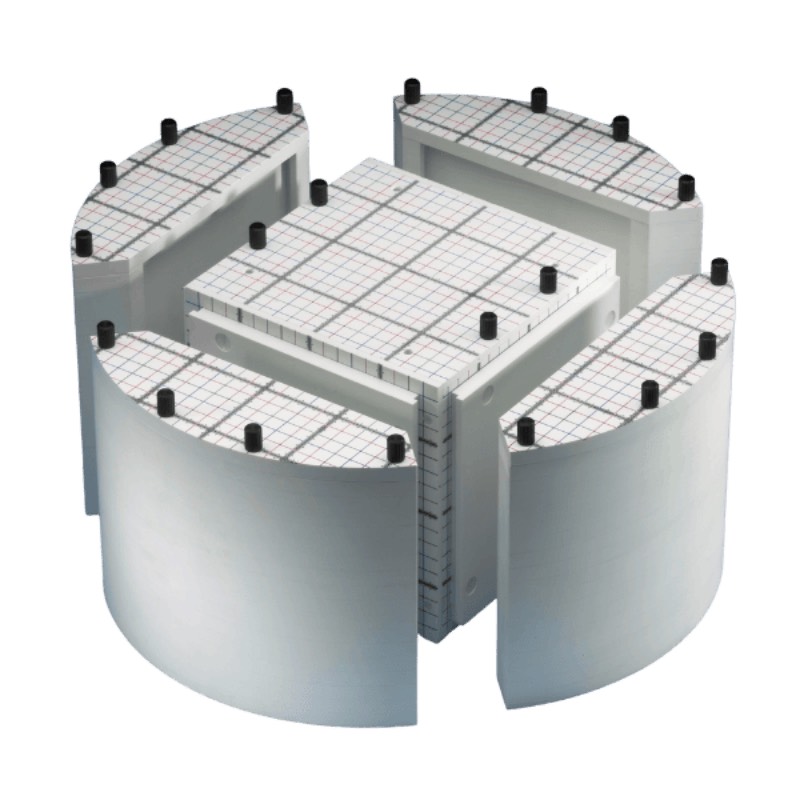

EASY CUBE Phantom optimized for Dosimetry & Imaging QA

The EASY CUBE supports end-to-end QA in radiotherapy and diagnostic workflows. With modular geometry and extension options (head, body, oval, cylinder), it enables versatile dosimetry setups. Detectors are embedded using RW3 adapters to ensure tissue equivalence. OEMs and researchers use EASY CUBE for commissioning and advanced QA workflows. Think LEGO for Medical Physicists.

EASY SLAB vs. EASY CUBE - Technical Details for QA Phantoms

| Feature | EASY SLAB Phantom | EASY CUBE Phantom |

|---|---|---|

| Material | Homogeneous RW3 Solid Water | RW3 Solid Water, modular segments |

| Dimensions | 300 × 300 × 300 mm or 400 × 400 × 300 mm | 180 × 180 × 180 mm (cube) |

| Modules | Stackable slabs in variable thicknesses | Head (Ø180 × 180 mm), Body (360 × 335 × 180 mm), Oval (360 × 180 × 180 mm), Cylinder (Ø320 × 180 mm) |

| Slab Set Composition | 1 × 1 mm, 2 × 2 mm, 1 × 5 mm, 29 × 10 mm, optional 20 mm or 60mm | Configurable per QA scenario |

| Detector Integration | Custom adapter plates for ion chambers (20+ versions) | Integrated adapter bar for ion chambers |

| Compatibility | Ion chambers, diode detectors, TLDs, EPIDs | Ion chambers, imaging systems, detectors |

| Transport | Includes transport & storage case | Includes transport & storage case |

| Typical QA Use | Routine QA, absolute dose verification, beam checks | End-to-end QA, imaging validation, commissioning |

Get in Touch

Integrate Reliable QA Phantoms into Your Radiotherapy & Imaging Workflows

Upgrade your radiotherapy QA and calibration workflows with RW3 Solid Water Phantoms. Contact us to integrate water-equivalent phantoms into your treatment planning and beam verification routines.

- Tissue-equivalent RW3 material for precise and reproducible QA measurements

- Modular phantom systems (slab, cube, MR) for routine, commissioning & end-to-end QA

- Over 30 years of experience in radiation therapy quality assurance solutions

Seamless Integration

Into Imaging QA Workflows

RW3 Solid Water Phantoms integrate effortlessly into radiotherapy and imaging environments. They support absolute dose calibration, beam quality assurance, and end-to-end testing for TPS commissioning. Compatible with standard ionization chambers, diode detectors, and MR imaging systems, RW3 provides consistent reference conditions for photon and electron applications.

Manufactured under ISO 13485 processes, RW3 phantoms comply with EU MDR 2017/745 and FDA standards. Each set includes verified documentation and traceable batch data for QA and OEM integration.

Our Applications

For Clinical and OEM QA

RW3 Solid Water Phantoms support calibration, verification, and validation across radiotherapy workflows:

- Routine QA: absolute dose and beam flatness checks

- TPS Commissioning: validation of treatment planning data

- End-to-End Testing: full workflow QA from imaging to beam delivery

- Detector Calibration: ion chamber and diode verification

- OEM Integration: custom phantom configurations for system testing

Machine-QA

Patient-QA

CT scan

MR imaging

Laser alignment

Dosimetry

Learn more about our projects

Discover how gKteso’s positioning solutions are applied in advanced radiotherapy systems worldwide. From prototype integration to clinical implementation, our projects demonstrate precision engineering in real treatment environments. Learn how we collaborate with OEM partners to shape the next generation of radiotherapy technology.

Learn more about …

Seamless surface scanner integration and live motion correction during treatment.

Learn more about …

Patient Positioning Systems by gKteso: Tailored for modern radiotherapy environments.

Schedule an appointment now!

Frequently Asked Questions

Are the phantoms compatible with all common QA and dosimetry detectors?

Yes. RW3-based phantoms (EASY SLAB, EASY CUBE, Head Phantom) are compatible with more than 60 different ionization chambers, diode detectors, TLDs, radiosensitive films, and EPID systems. MR-specific phantoms (AQUARIUS, THETIS) are MR conditional up to 3T and integrate seamlessly into MR QA workflows.

Can the phantoms be customized for OEM integration?

Yes. Adapter plates, detector inserts, RFID features, and custom configurations are available upon request. OEMs can integrate the phantoms into commissioning, calibration, and end-to-end system testing with FDA-ready and CE/MDR-compliant documentation.

How do RW3 Solid Water Phantoms support consistent QA results across different systems?

RW3 phantoms are manufactured under ISO 13485 and undergo CT-based homogeneity verification to ensure identical attenuation and scattering properties in every unit. This guarantees reproducible calibration and dose verification results, even when measurements are performed across multiple LINACs or OEM systems. Clinics and researchers benefit from globally comparable QA data without material-related deviations.

What are the main advantages of RW3 solid water material?

RW3 provides highly reproducible, tissue-equivalent properties (density 1.045 g/cm³). It is stable under radiation, durable for long-term use, and internationally recognized as the gold standard for QA and dosimetry. In addition, the material is scanned for any inhomogeneities in CT.

What makes RW3 phantoms suitable for both clinical and OEM environments?

RW3 phantoms combine clinical-grade precision with industrial scalability. Each system can be configured for daily QA, commissioning, or OEM testing through modular geometries and detector adapters. With CE/MDR and FDA documentation, they fulfill regulatory requirements for clinical validation while offering OEMs the flexibility to integrate them directly into R&D, prototype, or production QA workflows.

Explore more advanced QA & patient positioning solutions for radiotherapy

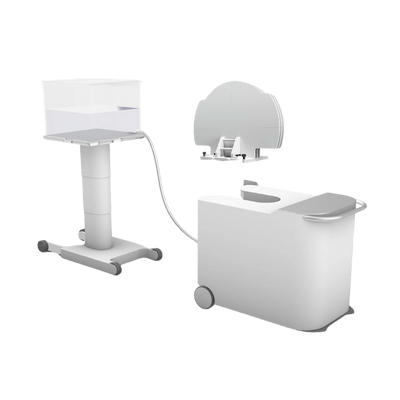

Customized OEM QA tools

Customized OEM QA Phantoms and Water Phantom Transport Units from gKteso provide tailored solutions for commissioning, routine QA, imaging calibration, and OEM system integration. With reproducible precision, MDR/FDA compliance, MR compatible options and scalable manufacturing, they ensure reliability in clinical and research environments worldwide.

RPS SGRT

The RPS SGRT provides image-guided precision without compromise for frameless radiotherapy treatments. It continuously monitors patient motion in real time to maintain exact positioning during irradiation. With intrafraction tracking and non-invasive setup, it ensures consistent accuracy and patient comfort throughout the procedure.

RPS HEAD

The RPS Head delivers high-precision positioning for cranial and head-and-neck radiotherapy. With integrated 6DoF motion control, it enables submillimeter correction in pitch, roll, and yaw even after the thermoplastic mask is fixed. Designed for stereotactic and image-guided workflows, it ensures stable geometry, minimizes repositioning, and supports accurate SGRT and CBCT verification throughout every treatment session.