gKteso Blog

Insights from the Frontlines

of Development

In this blog, we share applied knowledge from day-to-day engineering, mechatronic prototyping, and development challenges in real-world medical and industrial environments. Whether it’s a technical breakthrough in the lab, insights from international conferences, or feedback from customer site visits – each post gives you practical, unfiltered perspectives from our team.

Latest Activities

130 Years of X-Ray Imaging: From Röntgen’s Discovery to Modern Medical Technology

On January 23, 1896, Wilhelm Conrad Röntgen presented something the world had never seen before: the first X-ray image. This moment, unveiled in Würzburg, marked the beginning of modern diagnostic imaging and transformed medicine forever. What started as scientific curiosity became a cornerstone of diagnosis, therapy planning, and patient care.

Today, 130 years later – and just 150 kilometers away, we at gKteso continue to build on this legacy. With engineering teams in Schwarzenbruck and Bobingen, and strong ties to the medical technology hub around Erlangen, our work follows the same guiding principle: to look deeper, visualize the invisible, and turn discovery into real-world clinical impact.

From digital radiotherapy systems to imaging-compatible robotics and precision mechatronics, Röntgen’s breakthrough still echoes in every technology we help develop.

Here’s to 130 years of medical imaging innovation and to the countless lives improved because someone dared to look beyond what was visible.

Glaucoma Awareness Month: Advancing Precision to Protect Vision

January marks Glaucoma Awareness Month, highlighting a condition that often progresses without early symptoms yet remains one of the leading causes of irreversible blindness worldwide. Raising awareness is essential – but so is advancing the precision of diagnostic and surgical technologies that help protect what matters most: vision.

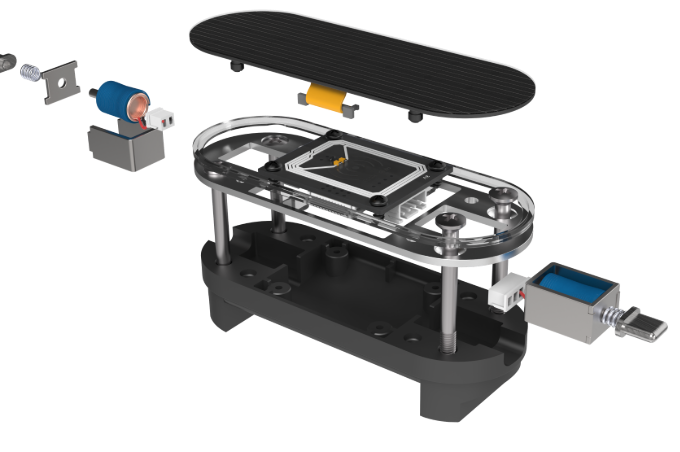

At gKteso, we are proud to support ophthalmic innovation with advanced motion systems designed specifically for ophthalmic surgery and imaging-based procedures. Developed for seamless OEM integration, our platforms enable ultra-precise positioning, smooth kinematics, and real-time motion control – capabilities that are critical in modern microsurgery, where even the smallest deviation can have significant impact.

By combining engineering precision with clinical requirements, our solutions help create stable, reliable surgical environments that support accuracy and confidence in glaucoma treatment and beyond.

To all clinicians, engineers, and researchers working to fight glaucoma: thank you for your dedication. Because when it comes to vision, every micron matters.

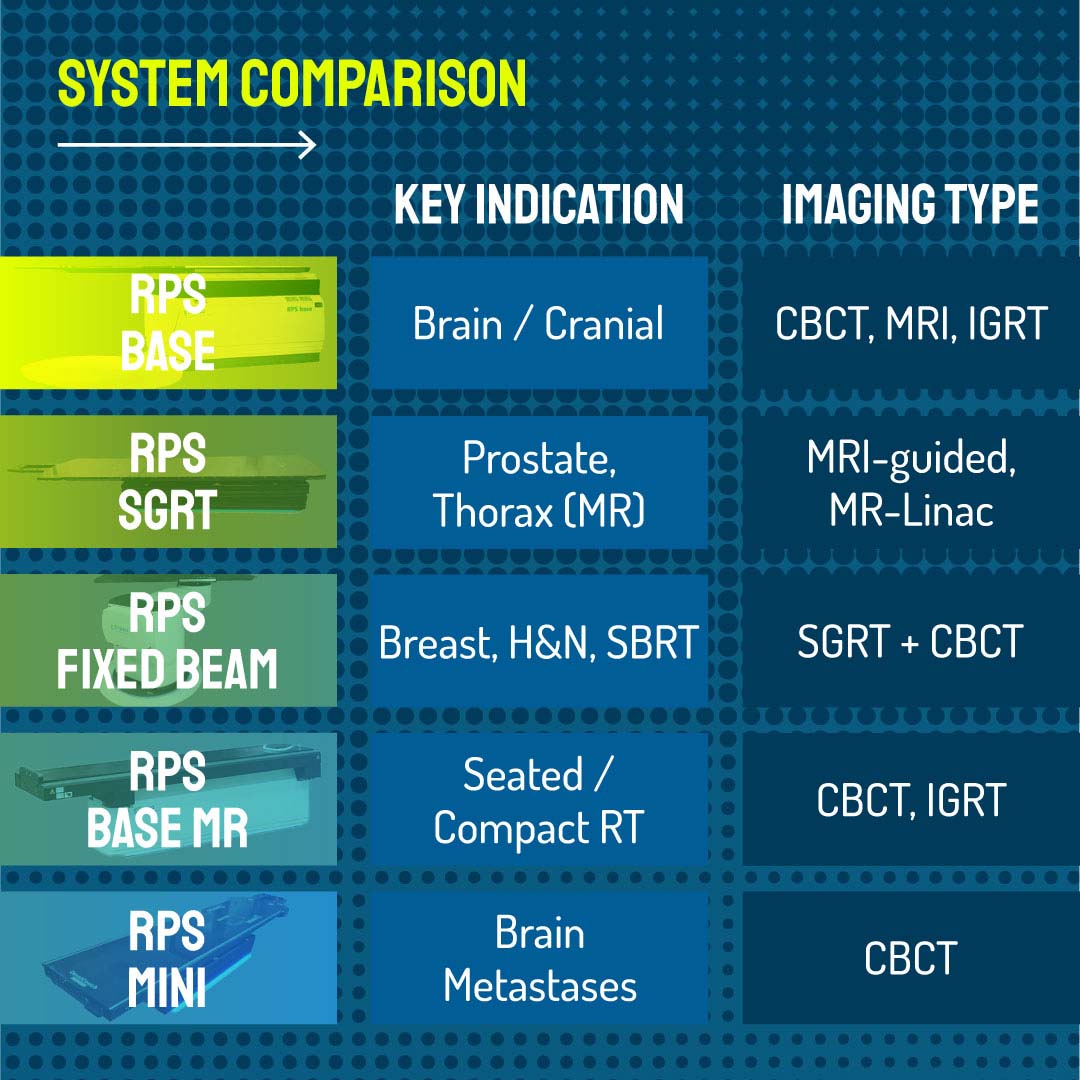

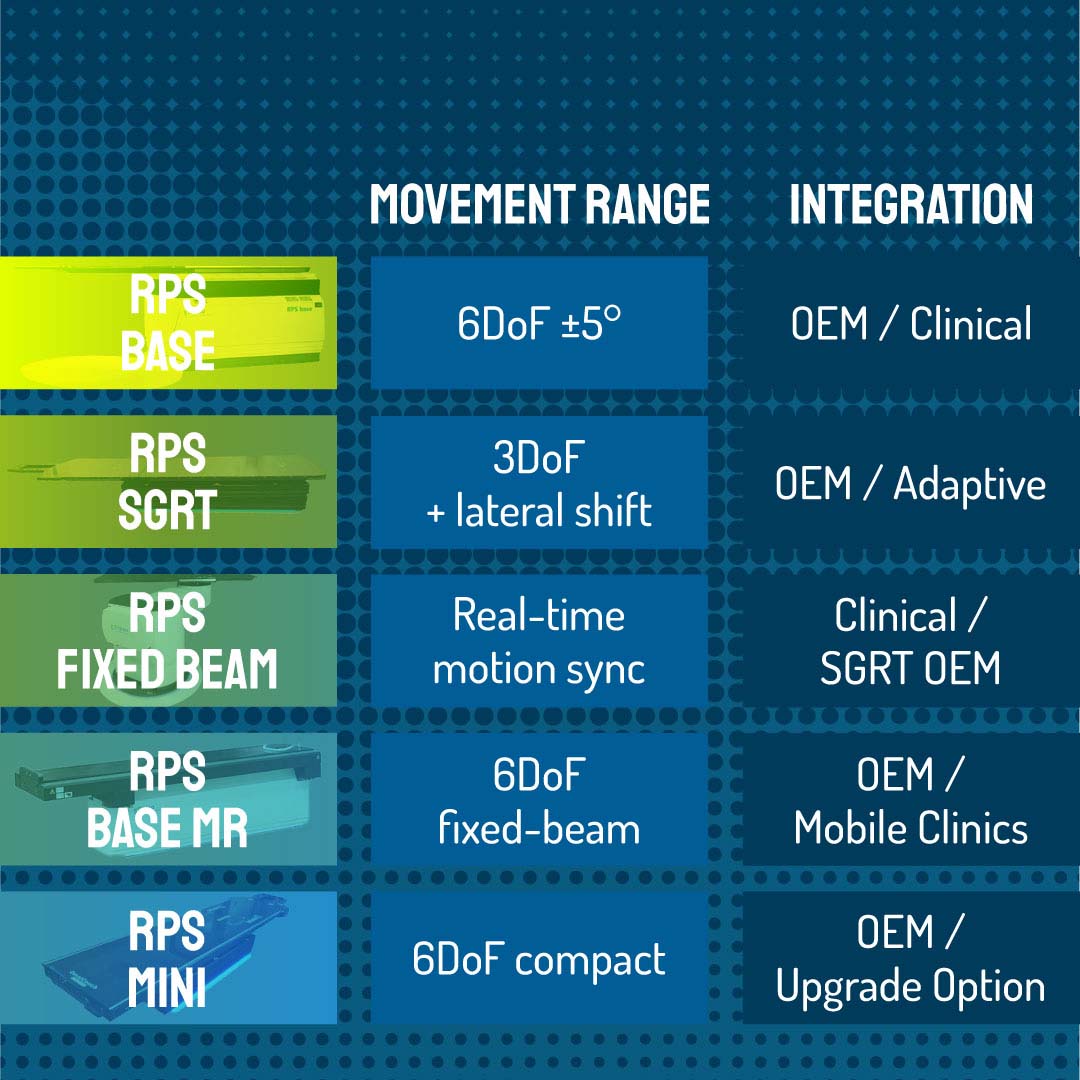

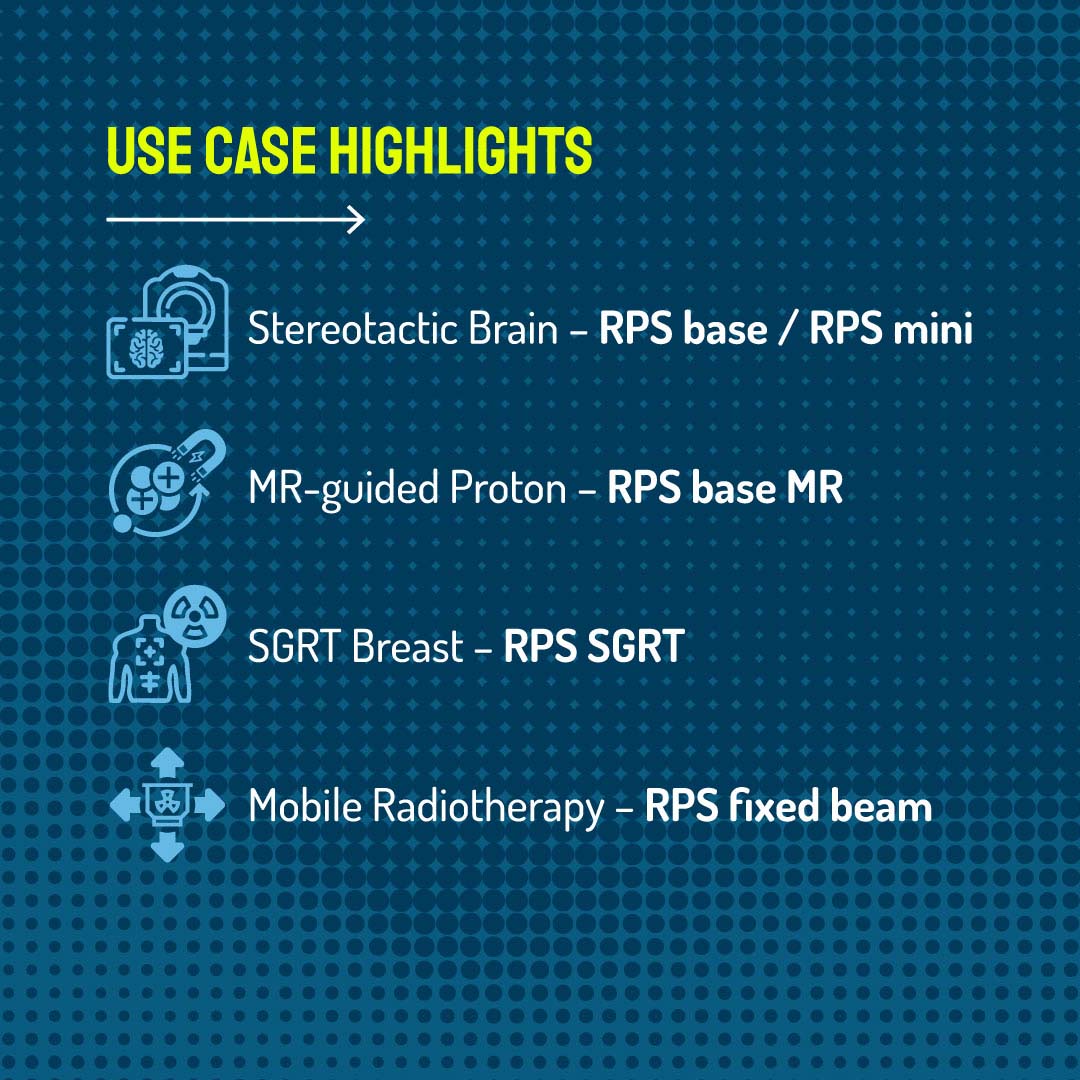

Choosing the Right Patient Positioning System: A Practical Guide for Radiotherapy Applications

Selecting the right patient positioning system is a critical decision – especially when workflows range from cranial stereotactic radiotherapy (SRT) to MR-guided treatments. Each application places different demands on imaging compatibility, motion control, and system integration.

To support informed decisions, our side-by-side system guide compares the key features across the gKteso RPS product line. It helps OEMs and clinical teams evaluate systems based on:

Use-case alignment

Imaging and modality compatibility

Integration paths for OEM and clinical environments

Motion capabilities and degrees of freedom

Whether you are developing a new OEM platform or upgrading an existing radiotherapy system, having clear technical insight is essential. Our approach combines transparent comparison with tailored engineering consulting, ensuring that each solution fits both clinical requirements and system architecture.

The goal is simple: technical clarity that leads to confident decisions – and positioning systems that truly support modern radiotherapy workflows.

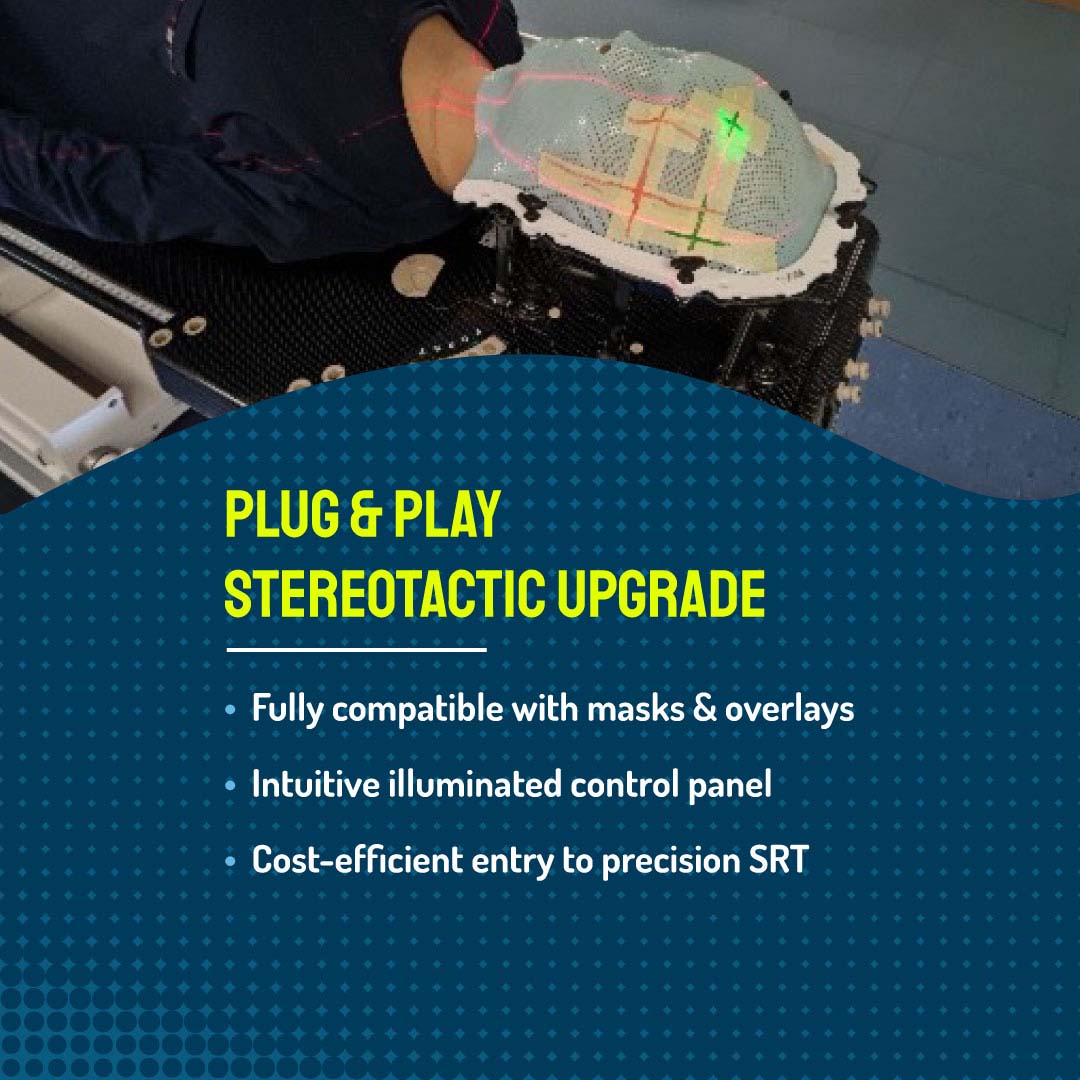

RPS Head: 6DoF Precision Made Simple for Cranial Radiotherapy

Precise and repeatable patient positioning is essential in cranial radiotherapy – especially for stereotactic, IGRT-based, and motion-sensitive treatment workflows. The RPS Head is gKteso’s versatile solution designed to deliver platform-ready 6DoF precision exactly where it is needed: directly at the mask board.

By enabling accurate pitch, roll, and yaw correction without requiring changes to the existing couch or platform, the RPS Head integrates seamlessly into established clinical environments. It is fully compatible with standard mask systems and indexing solutions, making it easy for OEMs to adopt without disrupting proven workflows.

Designed with clinical usability in mind, the intuitive adjustment concept supports fast setup, high reproducibility, and long-term mechanical stability. Whether deployed as part of a dedicated cranial solution or within a modular positioning ecosystem, the RPS Head helps OEMs deliver high-precision cranial positioning – without adding unnecessary complexity.

6DoF for everybody. Engineered for OEM platforms.

From High-Speed Motion to New Year’s Momentum: Looking Ahead to 2026

As 2025 comes to a close, we want to take a moment to say thank you – to our partners, customers, and our entire team across Bobingen, Schwarzenbruck, and beyond. The past year has been shaped by engineering breakthroughs, product launches, new collaborations, and many late nights in the lab. None of this would be possible without the trust, passion, and curiosity shared across our network.

Together, we transformed ideas into working technology, advanced precision engineering, and strengthened partnerships that drive meaningful innovation in MedTech. Each milestone reflects a collective effort – across disciplines, locations, and teams.

Now, we look ahead to 2026 with momentum. New prototypes, upcoming launches (at least three are already on the roadmap), fresh ideas, and even stronger collaborations are on the horizon.

We wish you a Happy New Year – defined by precision, purpose, and just a little rocket science. 🥂

Season’s Greetings from gKteso: Precision, People, and a Moment to Pause

As the year draws to a close, the holiday season offers a chance to step back and appreciate what truly matters. At gKteso, our passion is turning precision engineering into meaningful care throughout the year – but Christmas is also a time to slow down, reconnect, and reflect.

This season reminds us that innovation is driven not only by technology, but by the people behind it: engineers, partners, customers, and collaborators who share ideas, challenge boundaries, and build solutions together. Their trust and commitment are what make progress possible.

From our teams in Bobingen and Schwarzenbruck, we extend our warmest holiday wishes. May this Christmas bring you time to recharge, enjoy moments of calm, and look ahead with curiosity and optimism. We hope it’s filled with good conversations, well-deserved rest, and maybe even a few cookies along the way.

Merry Christmas and season’s greetings from all of us at gKteso. 🎁

A Cozy Year-End Tradition at gKteso: Coming Together in Schwarzenbruck

As the year comes to a close, traditions become especially meaningful. Last Friday, our Schwarzenbruck team gathered for its annual Christmas dinner – a cozy evening centered around roasted goose, mulled wine, and great conversations. Despite the cold winter temperatures, the atmosphere was warm, open, and full of shared laughter.

Moments like these highlight what truly matters beyond day-to-day project work. The evening was not only about good food, but about connection, appreciation, and taking a collective breath after an intense and demanding year. Bringing people together creates space to reflect on what we have achieved and the challenges we have overcome – both professionally and personally.

Even in uncertain times, there is always room for optimism. The spirit of Christmas reminds us to pause, reconnect, and look ahead with confidence and hope.

A heartfelt thank you to everyone who joined and made this tradition another memorable moment at gKteso.

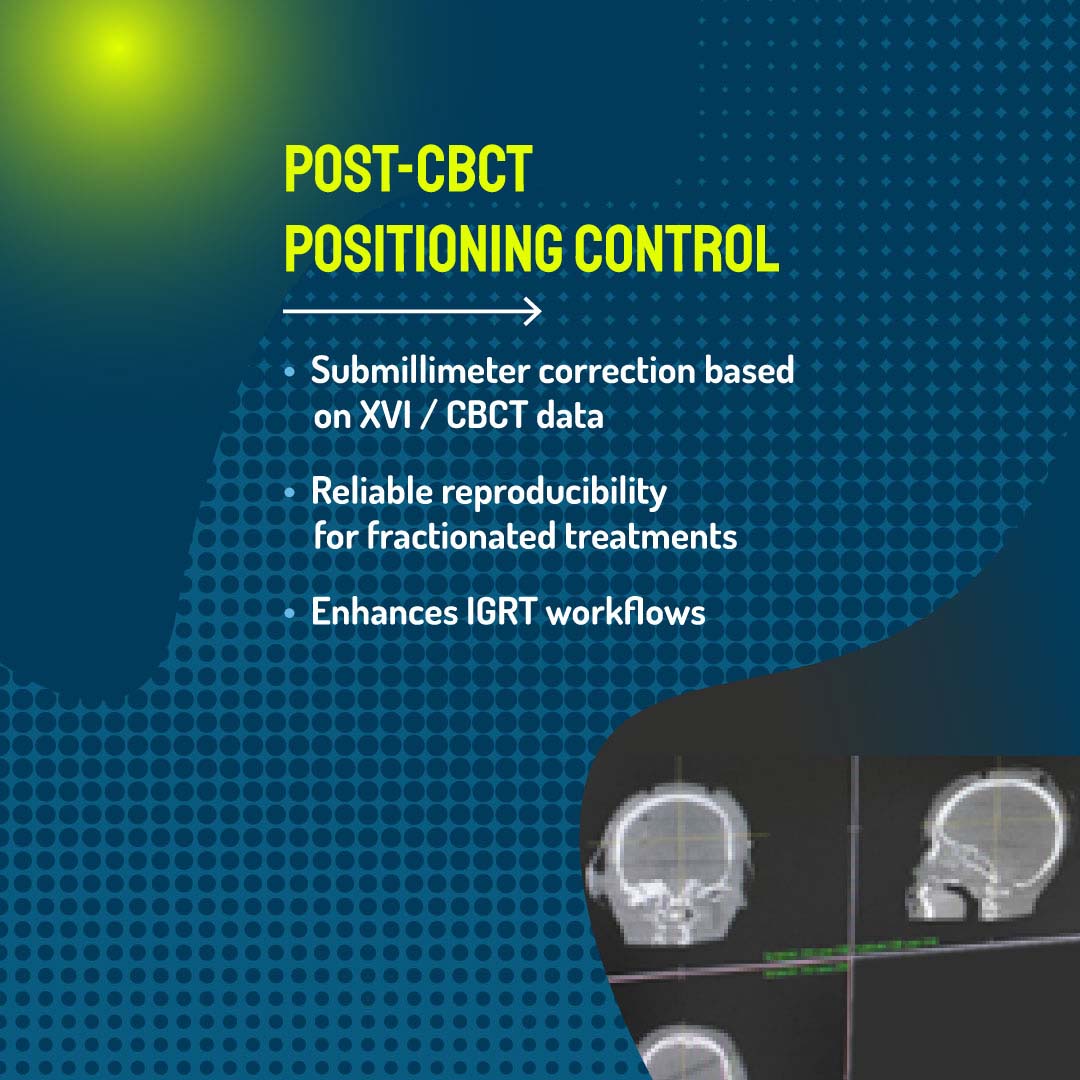

Submillimeter Precision for Intracranial Stereotactic Radiotherapy

When treating brain metastases, precision is critical – especially near sensitive structures such as the brainstem or optic nerves. Even minimal deviations can affect both treatment safety and outcome. The RPS mini is designed to support these demanding clinical scenarios by delivering submillimeter 6DoF corrections immediately after Cone Beam CT imaging.

Optimized for high-precision stereotactic radiotherapy (SRT) workflows, the system enables accurate patient alignment for complex cranial cases, whether in single-fraction SRS or fractionated treatment protocols. Its precise motion control improves reproducibility and confidence in dose delivery, even in challenging anatomical situations.

The RPS mini integrates seamlessly into existing radiotherapy environments and is fully compatible with thermoplastic masks and immobilization overlays. Importantly, it brings advanced positioning capabilities without requiring a complete system overhaul – making it an efficient upgrade path for modern treatment centers.

With the RPS mini, high-precision cranial radiotherapy becomes more accurate, flexible, and accessible.

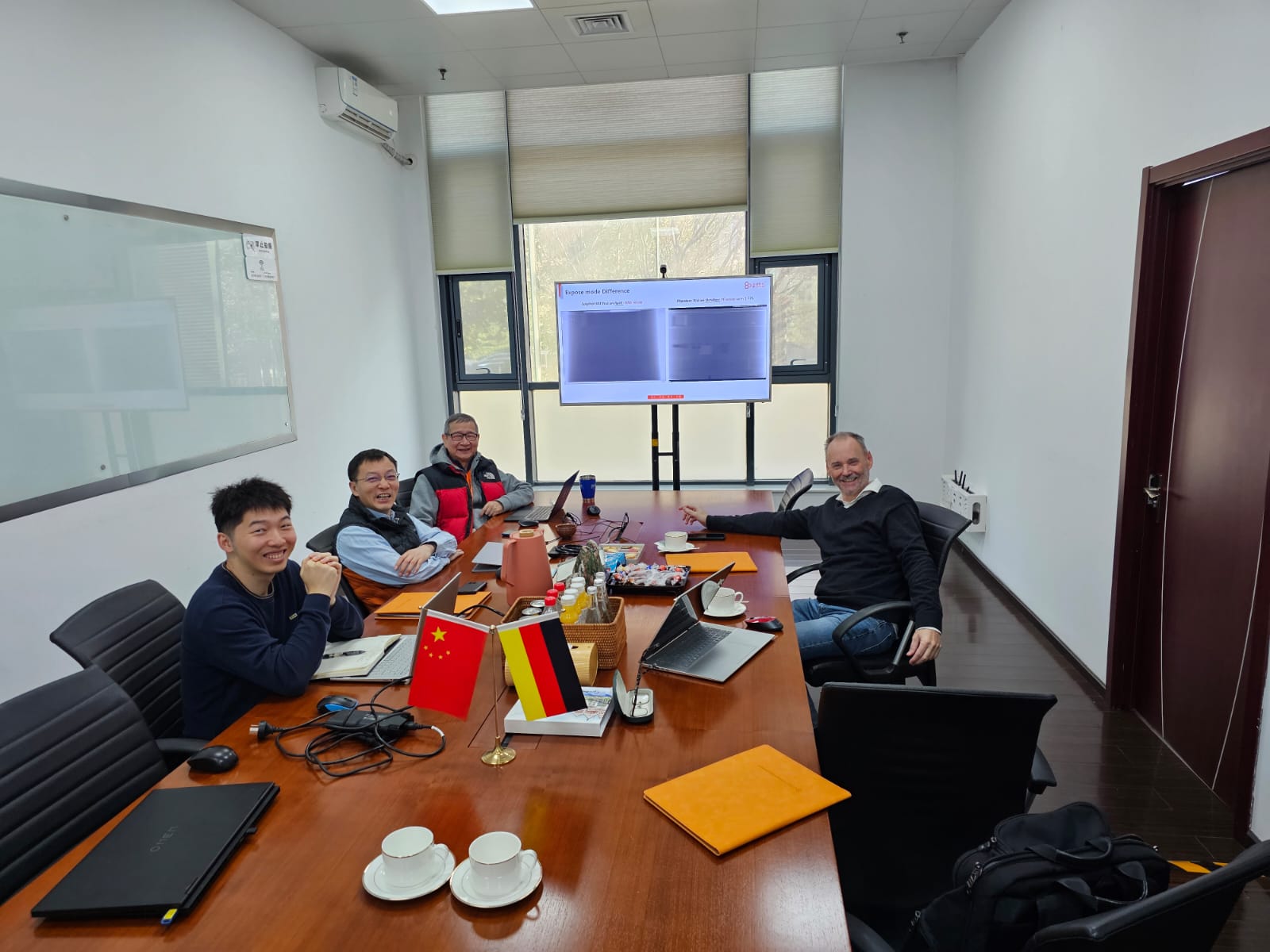

Next-Gen Imaging: Global Collaboration Driving Radiotherapy Innovation

Modern radiotherapy and diagnostic systems rely on imaging solutions that deliver maximum precision and stability. This is why we are partnering with E-COM Technology in China to integrate the next generation of X-ray detectors into advanced OEM systems. During their recent visit to Beijing, Guido Kübler and Rainer Kaltschmidt focused on testing, interface optimization, and fine-tuning system integration.

Working together on-site made it possible to address technical challenges directly – whether related to signal quality, detector sensitivity, or software and interface alignment. This hands-on collaboration lays the foundation for imaging solutions that set new benchmarks in performance, efficiency, and clinical reliability.

Beyond the engineering sessions, the visit also offered opportunities for cultural exchange, strengthening the trust and understanding that long-term partnerships rely on.

A sincere thank-you to E-COM Technology for the warm welcome, valuable discussions, and strong technical cooperation. Together, we are shaping the future of medical imaging.

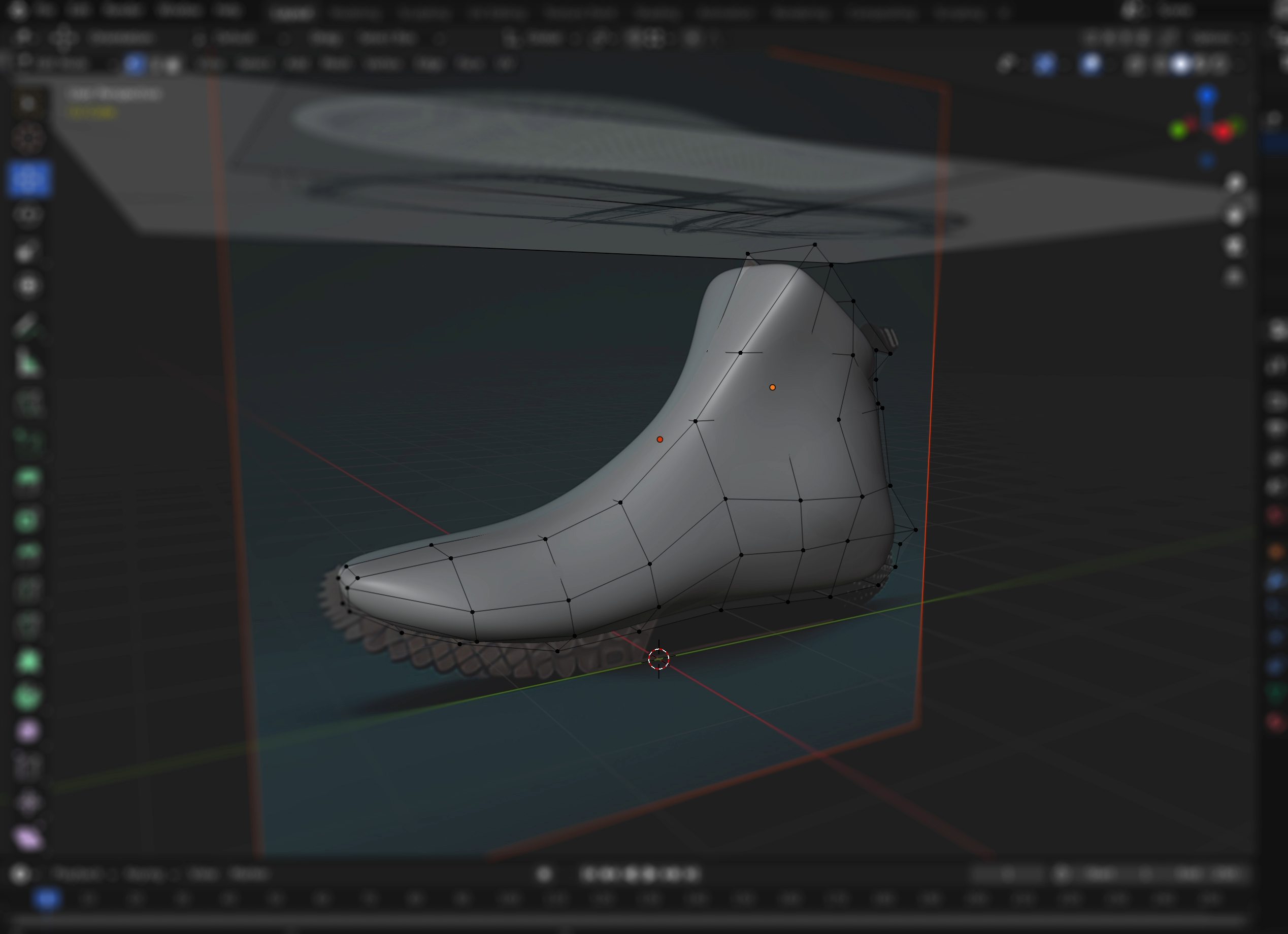

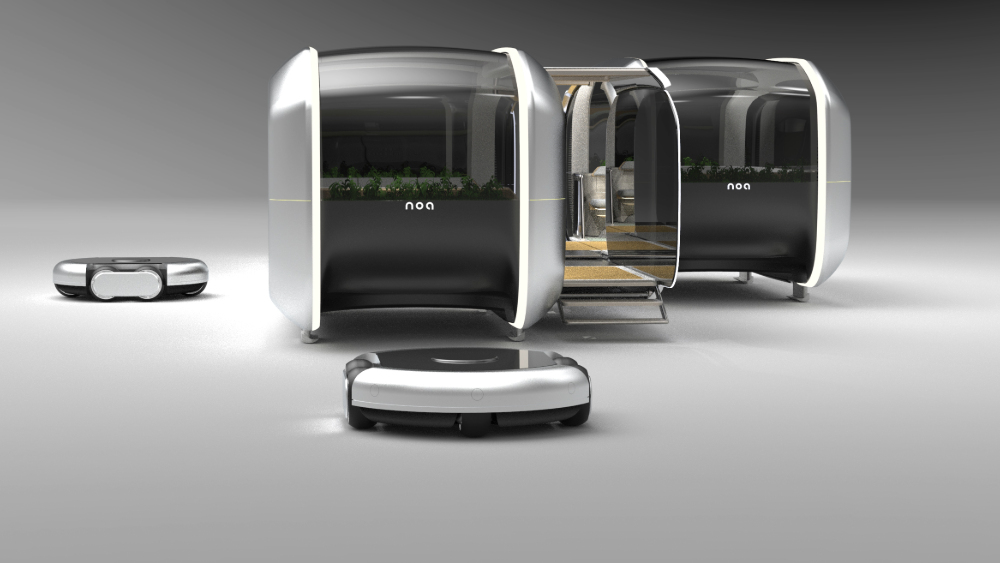

From Digital Vision to Tangible Innovation: How gKteso DaaS Accelerates MedTech Development

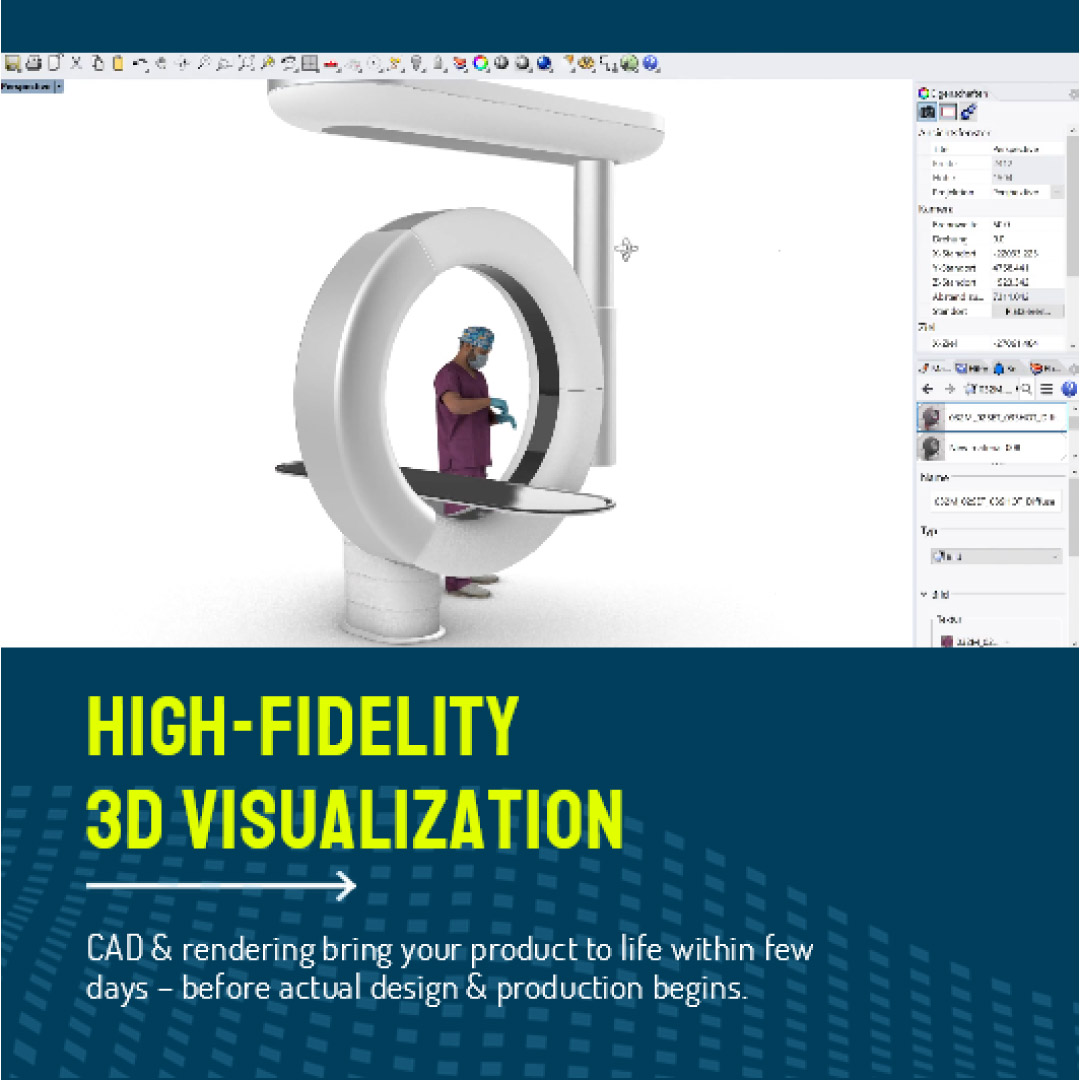

Bringing medical technology ideas to life requires more than design – it requires clear visualization, rapid iteration, and seamless transition into manufacturing. With gKteso Design as a Service (DaaS), OEMs gain an end-to-end process that transforms digital concepts into clinical-ready products.

We start with high-fidelity 3D visualizations, using CAD and photorealistic rendering to bring product ideas to life within days – long before physical design or production begins. These visual assets help align teams and stakeholders early, reducing uncertainty and speeding up decision-making.

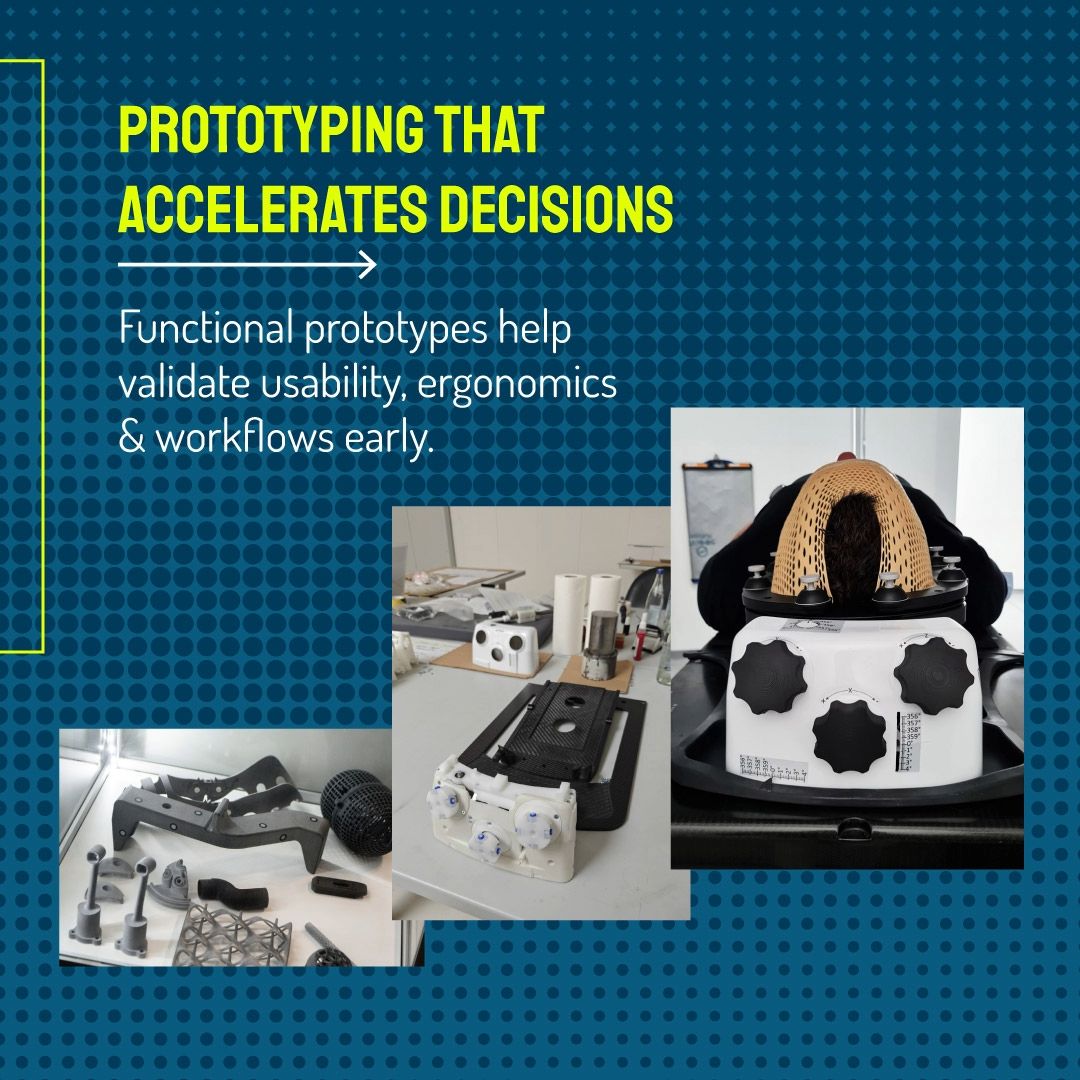

Next, we create functional prototypes that allow OEMs to validate ergonomics, usability, form, and workflow integration at an early stage. This hands-on approach ensures that every design works not only on screen but also in the clinical environment.

Our support continues all the way to production-ready design, enabling a smooth transition into scalable manufacturing—whether with our supplier network or yours.

At gKteso, our goal is simple: turning strong ideas into market-ready medtech products that deliver measurable impact.

IOLC 2025: A Human-Centered Finale at the Champalimaud Foundation

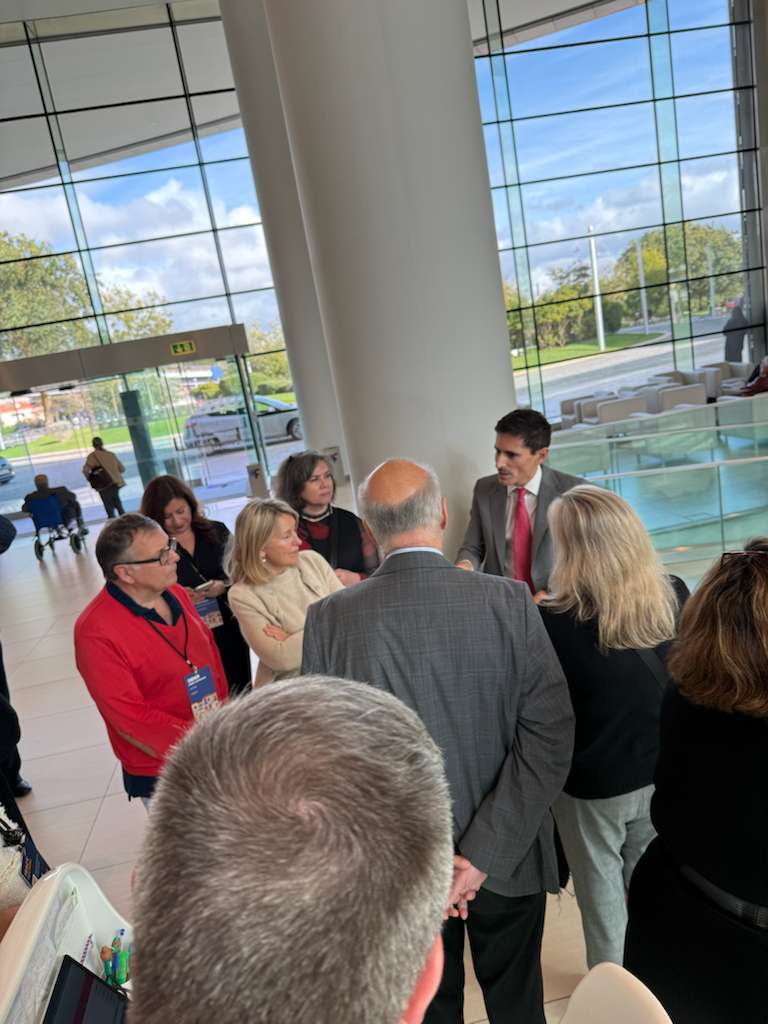

Day 3 of the 9th International Oncology Leadership Conference in Lisbon delivered a powerful reminder of what truly drives progress in cancer care: people. Hosted at the iconic Champalimaud Foundation, the final sessions highlighted why innovation in oncology must remain deeply human – whether through advances in psycho-oncological support or by recognizing the essential yet often overlooked role of pharmacists in integrated cancer treatment.

Across all discussions, one message stood out clearly: meaningful impact requires global collaboration, equitable access, and a commitment to bringing science into real-world practice. With the Atlantic coastline just outside the conference walls, the atmosphere underscored the urgency and responsibility that come with shaping the future of cancer care.

Together with our partner EHMET Health, we continue to demonstrate what becomes possible when administrators, clinicians, and engineers work in a shared language – creating pathways toward more connected, accessible, and patient-centered oncology solutions.

IOLC 2025: Turning Oncology Leadership Into Real-World Impact

Earlier this month, global oncology leaders gathered in Lisbon for the 9th International Oncology Leadership Conference (IOLC 2025) to discuss a central question: How do we transform clinical needs into meaningful innovation?

The sessions covered a broad spectrum of challenges – expanding worldwide access to cancer care, accelerating cell therapy, integrating AI into workflows, and translating emerging technologies into real clinical environments. The key takeaway was clear: leadership in oncology is not defined by strategy alone. It is defined by execution, collaboration, and the ability to turn expertise into tangible results.

Together with our partner Michael Teicher from EHMET Health and our CEO Guido Kübler, we joined the conversations to listen, exchange insights, and contribute our perspective. At gKteso, we believe that bridging administrators, clinicians, and engineers is essential to driving progress.

From clinical access to OEM-ready radiotherapy technologies, we are proud to be part of the discussions shaping the future of cancer care.

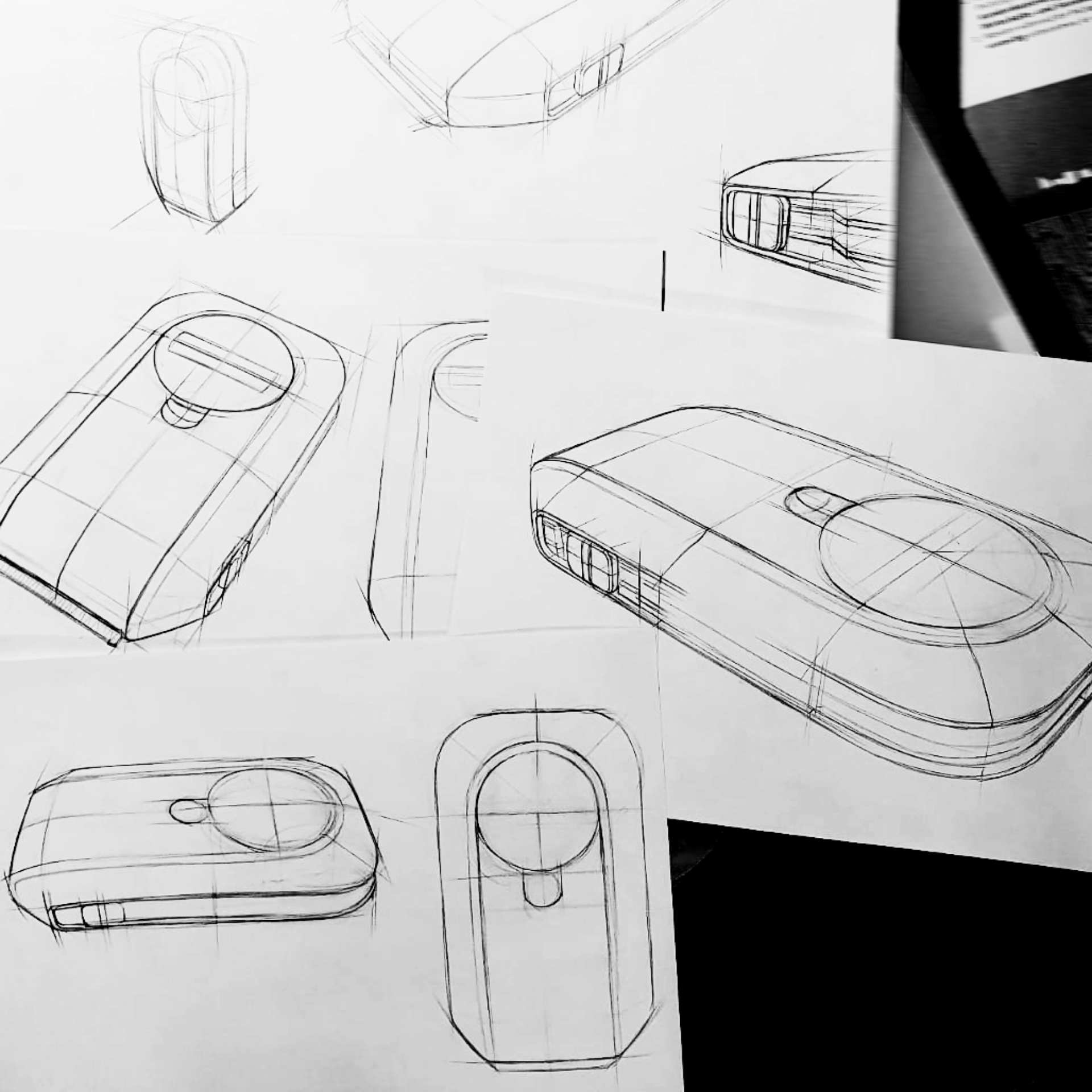

Turning Complexity Into Clarity: Introducing gKteso Design as a Service

Medical technology products start with ideas – sometimes rough sketches, sometimes complex visions. With gKteso Design as a Service (DaaS), we help OEMs turn these early concepts into functional, human-centered industrial designs that are ready for real clinical environments.

Our approach begins with transforming first sketches into clear design concepts that combine usability, ergonomics, and recognizable brand identity. Through iterative concept development, we explore multiple design directions, enabling faster decision-making and more confident product strategies.

With deep medtech engineering expertise, we ensure that every design aligns with clinical workflows, regulatory expectations, and technical constraints from day one. This means your product not only looks right – it works in real-world healthcare settings.

Whether you need support across the full design workflow or seamless integration into your existing teams, we help accelerate your development process and sharpen your competitive edge.

Your idea. Your product. With gKteso.

International Day of Radiology 2025: Celebrating the Technology That Helps Us See What Matters

Today we celebrate the International Day of Radiology 2025 – a moment to recognize the essential role that imaging plays across the entire spectrum of modern medicine. From early diagnostics to precise therapy planning, radiology is the visual foundation that guides clinical decision-making every day.

At gKteso, we honor the clinicians, engineers, and researchers who continuously advance imaging technologies enabling earlier detection, more accurate targeting, and more efficient workflows. Their work shapes the future of patient care, one scan at a time.

Our own contribution lies in developing mechatronic solutions for radiotherapy and radiology that integrate seamlessly into MR, CT, and X-ray environments. These systems support imaging precision, workflow consistency, and smooth integration into OEM and clinical settings.

Imaging may be the silent guide in every treatment decision, but its impact is unmistakable. Here’s to the field that helps us see clearly and to the people who make it possible.

Celebrating International Medical Physics Day 2025: Honoring the Science Behind Precision Care

Today, on the birthday of Marie Curie, we celebrate the experts who make modern radiotherapy, imaging, and diagnostics as precise and reliable as they are: medical physicists. Their work forms the scientific backbone of high-quality cancer care – often behind the scenes, but always essential.

From enabling sub-millimeter patient positioning to validating complex dose distributions and developing advanced QA methods, medical physicists ensure that innovation becomes safe, effective clinical practice. Their contributions bridge the gap between cutting-edge technology and real-world patient care, empowering clinicians to deliver treatments with confidence and accuracy.

At gKteso, we are proud to collaborate with physicists worldwide who bring scientific rigor, problem-solving, and empathy into daily clinical routines – from the lab bench to the linac.

Today, we honor these quiet heroes whose expertise drives progress in medical science. And we celebrate Marie Curie, whose legacy continues to inspire generations of innovators shaping the future of healthcare.

Introducing gKteso Design as a Service: From Concept to Clinical-Ready Solutions

At gKteso, we’re expanding our support for OEM partners with a new offering: Design as a Service (DaaS). This service enables medical technology teams to move from early concept sketches to fully realized, clinically ready products – efficiently, precisely, and with a strong focus on usability and manufacturability.

Whether you are starting from a blank page or looking to modernize an existing system, our DaaS offering covers the complete industrial design workflow. This includes functional concept development, visual design, prototyping, ergonomics, material selection, and guidance for scalable production.

Need full end-to-end support? We can bring your entire product vision to life. Already working with internal teams or trusted partners? Our standalone design modules integrate seamlessly into your existing development process.

From cleanroom-compatible components to accessories for radiotherapy and advanced mechatronics, our engineering and design experts transform complexity into clarity. A special thanks goes to Michael Schnaus, whose creative expertise drives this new chapter forward.

Meet gKteso at ASTRO 2025 in Chicago: Advancing Precision in Radiotherapy

From image-guided patient positioning to high-precision beam shaping, engineering excellence continues to drive progress in modern radiotherapy. This September, we’re bringing our expertise to one of the field’s most influential events: the 67th American Society for Radiation Oncology (ASTRO) Annual Meeting, taking place September 28–30 in Chicago.

ASTRO 2025 will once again gather clinicians, researchers, physicists, and industry partners to explore the latest innovations shaping cancer treatment. As part of this global community, gKteso is committed to supporting OEMs with technologies that improve accuracy, efficiency, and workflow integration across radiotherapy systems.

Our Managing Director, Stefan Ueltzhoeffer, will be on site to meet partners, discuss emerging trends, and explore how OEM-ready engineering solutions can accelerate product development – from patient positioning systems to next-generation mechatronics for radiotherapy environments.

If you’re attending ASTRO and want to learn how precision engineering can elevate your radiotherapy innovation pipeline, we’d love to connect.

Exploring the Future of Cardiovascular Innovation at ESC 2025 in Madrid

Hola Madrid! Last weekend, our Managing Directors Guido Kübler and Stefan Ueltzhoeffer attended the European Society of Cardiology (ESC) Congress 2025 – one of the most influential events in cardiovascular medicine. The congress offered a deep dive into the rapidly evolving landscape of cardiology, where advanced imaging, AI-driven diagnostics, and breakthrough clinical data are reshaping care across disciplines.

From real-time decision-support tools to novel visualization technologies, this year’s ESC highlighted how digital intelligence and precision imaging are accelerating progress in both acute and long-term cardiac care. The interdisciplinary exchange underscored how engineering, clinical expertise, and data science increasingly converge to improve outcomes.

A big thank-you to everyone who shared their insights, perspectives, and energy – and to the ESC team for organizing yet another outstanding event. We’re excited to continue exploring how cross-disciplinary innovation can drive the next wave of medical technologies.

Schwarzenbruck Becomes gKteso MedSolutions GmbH: A New Chapter in the gKteso Group

Almost one year after acquiring LAP Sued GmbH, the integration is now officially complete. Our CEO Guido Kübler and Managing Director Stefan Ueltzhoeffer have signed the final documents at the notary – marking the full legal transition of the Schwarzenbruck site into the gKteso Group.

With its new name, gKteso MedSolutions GmbH, the location strengthens our position in radiotherapy engineering and expands our technological portfolio. From Multileaf Collimators (MLCs) to QA phantoms and other precision components, the Schwarzenbruck team adds critical expertise that enhances our capabilities across imaging, positioning, and beam-shaping technologies.

What began in December 2023 as a strategic step to deepen our radiotherapy know-how has now become a fully integrated part of our organization. Together, we are building a future defined by innovation, seamless system integration, and strong partnerships – creating solutions that support OEMs and clinics worldwide.

Welcome to the gKteso Group, gKteso MedSolutions GmbH.

A Summer Tradition at gKteso: Team Spirit That Drives Medical Engineering

Once a year the courtyard at our Bobingen site turns into a place where engineering, teamwork and community come together. The gKteso Sommerfest has grown into a small tradition and shows what stands behind our radiotherapy systems and motion technology. People build technology, not machines.

Teams from Bobingen and Schwarzenbruck spend the afternoon together. Long tables fill the yard, fresh beer and Spanferkel set the tone and the kids turn the bouncy castle into the busiest test rig of the day. The mix of engineering talk and relaxed summer moments creates an atmosphere that connects colleagues across departments and locations.

Medical engineering often needs focus, precision and long development cycles. Days like this show the other side of our work. Trust, collaboration and a shared spirit move our projects forward and shape the solutions we bring to radiotherapy and patient positioning.

The Sommerfest reminds us that real innovation grows in teams that enjoy working together. It supports a work culture where people feel connected and carry that energy back into development, integration and testing.

If you want to see a glimpse behind the scenes, take a look at the video from the event. It shows the campus in summer light and the atmosphere that makes our company culture strong.

From Conference Connection to Collaboration: Building New Stories in MedTech

Great ideas often begin with the right conversation. When we first met Mustafa Kadhim at ESTRO 2025 earlier this year, it immediately became clear that we shared the same drive: making innovation in MedTech tangible, authentic, and meaningful.

This week, that initial connection evolved into a focused virtual workshop with our CEO Stefan Ueltzhoeffer and Marketing Manager Larissa Kroder. Together, we explored how to communicate complex OEM engineering stories in a way that is clear, credible, and creatively aligned with real clinical value.

From motion control intelligence to high-precision radiotherapy systems, gKteso’s technologies have a strong narrative behind them – and this collaboration aims to bring that story into the spotlight.

What started as a conference encounter is now moving toward something bigger: a partnership built on transparency, shared expertise, and a passion for impactful communication.

What’s next? Stay tuned something exciting is on the way.

Innovation doesn’t happen at a desk alone.

True innovation doesn’t happen behind closed office doors – it happens where technology is built, tested, and refined. A recent behind-the-scenes moment captured our CEO Guido Kübler, owner and passionate engineer, visiting our team at the Schwarzenbruck site near Nuremberg in the midst of developing a new medical imaging system.

While we can’t reveal the product details just yet, what you can see is the foundation of gKteso engineering: teamwork, curiosity, collaboration, and shared technical passion. These values turn ambitious concepts into clinical-ready solutions.

At gKteso, high-tech requires human connection. Our culture is built on working side-by-side – engineers, specialists, and management alike – right where the innovation happens: at the product itself. Ideas grow stronger when discussed openly, tested hands-on, and shaped directly on the hardware.

Because in medtech engineering, the best solutions emerge not from desks, but from teams working together toward a shared vision.

Inside the Lab: Where Imaging Innovation Meets Regulatory Precision

Somewhere in a quiet corner of our lab, a small but powerful device is doing what it does best: emitting X-rays and keeping secrets. This week, our “secret box” underwent official testing by radiation protection authorities – an essential step that always brings a blend of tension, technical focus, and, of course, plenty of coffee.

Although it looks like a prop straight out of a Cold War film, this unit plays a crucial role in advancing our imaging and shielding designs. Here, we simulate real imaging scenarios, experiment with materials, and validate new concepts to ensure compliance, safety, and performance – long before systems reach OEM development lines or clinical environments.

Through rapid prototyping, fast iteration, and hands-on testing, we push radiotherapy engineering forward with speed and precision. This is how smarter, safer, and more efficient imaging components come to life.

More insights coming soon – once we get the green light (literally).

RPS base MR: MR-Compatible Precision for Adaptive Radiotherapy

High-field imaging, real-time plan adaptation, and full-body treatment coverage demand a positioning platform built specifically for MRI-guided workflows. The RPS base MR delivers exactly that – combining MR compatibility with precise 3DoF motion control and workflow-optimized engineering.

Designed for MRI-guided photon and proton therapy, the non-magnetic platform integrates seamlessly into MRI environments with a low entry height and extended travel ranges. With 2600 mm longitudinal motion, enhanced lateral mobility, and submillimeter accuracy, it enables reliable alignment even for off-center or large-field treatments.

The system is ideally suited for adaptive radiotherapy, supporting distortion-free imaging and real-time anatomical adjustments for regions such as the prostate and thorax. This enhances clinical workflow efficiency while enabling precision-driven plan adaptation.

Built-in patient comfort features – such as integrated coil and headphone routing – reduce cable clutter, shorten setup times, and create a calmer scanning experience.

The RPS Base MR brings stability, flexibility, and imaging clarity to the next generation of MR-guided therapy.

RPS fixed beam: Precision and Stability for Gantry-Less Radiotherapy

Gantry-less radiotherapy is not a compromise – it’s an opportunity to create smarter, more flexible, and cost-efficient treatment environments. The RPS fixed beam system is engineered specifically for ion beam and bore-type photon setups that require uncompromising precision, reproducibility, and workflow adaptability.

With a 6DoF robotic couch and ultra-rigid fixation, the system offers ±5° angular correction, submillimeter accuracy, and simultaneous movement around the isocenter. Its high load capacity of up to 200 kg ensures stable, repeatable positioning even for challenging indications or non-standard patient anatomies.

Designed for clinical and OEM integration, RPS Fixed Beam supports thermoplastic mask systems, headrests, carbon baseplates, indexing accessories, and advanced immobilization techniques. Its flexibility enables upright, horizontal, and seated treatment workflows – ideal for compact rooms, mobile units, or decentralized proton centers.

From proton therapy to stereotactic applications and penumbra-sensitive workflows, RPS fixed beam provides the precision needed for modern image-guided radiotherapy.

Cost-efficient. Modular. Future-ready.

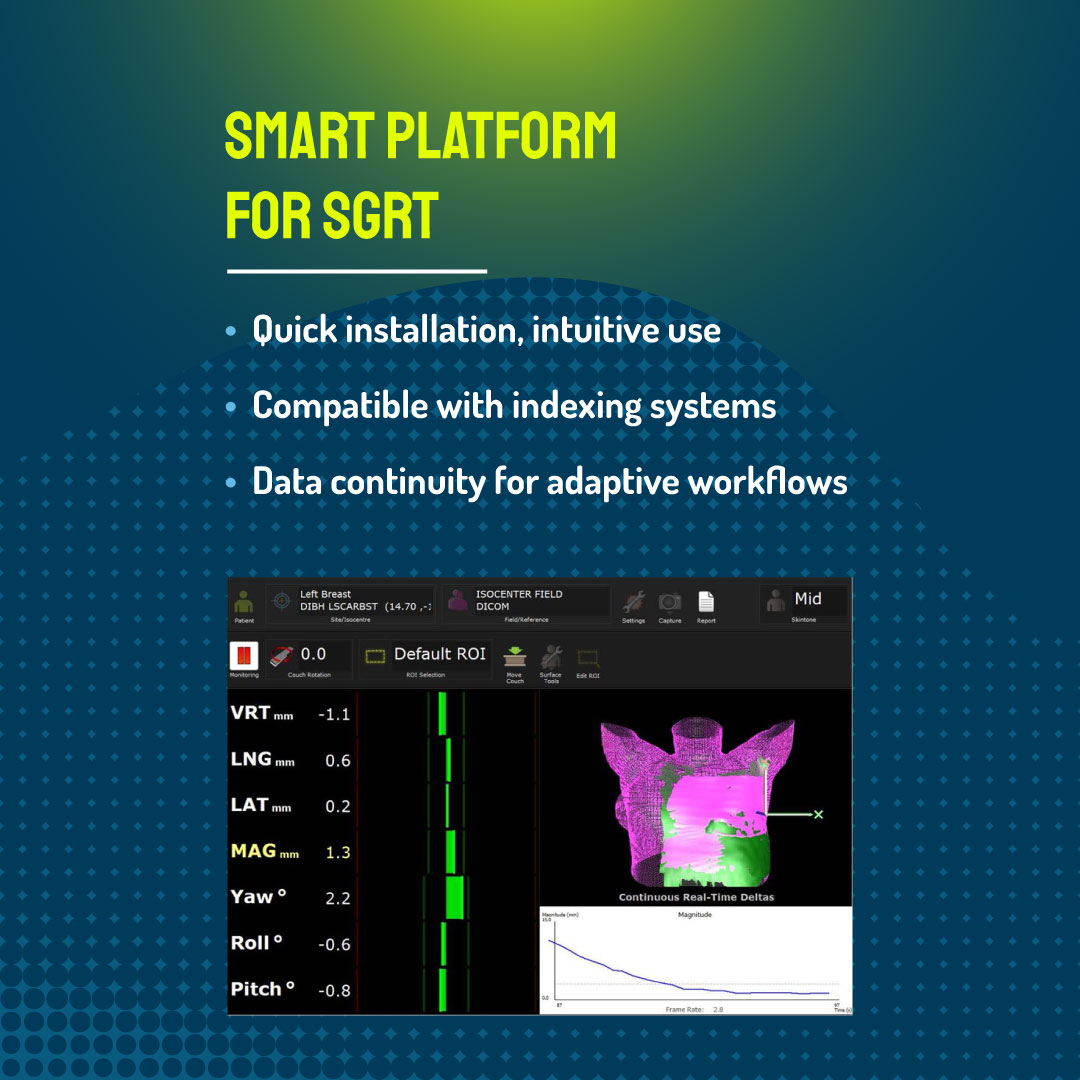

RPS SGRT: Real-Time Motion Control for Frameless Radiotherapy

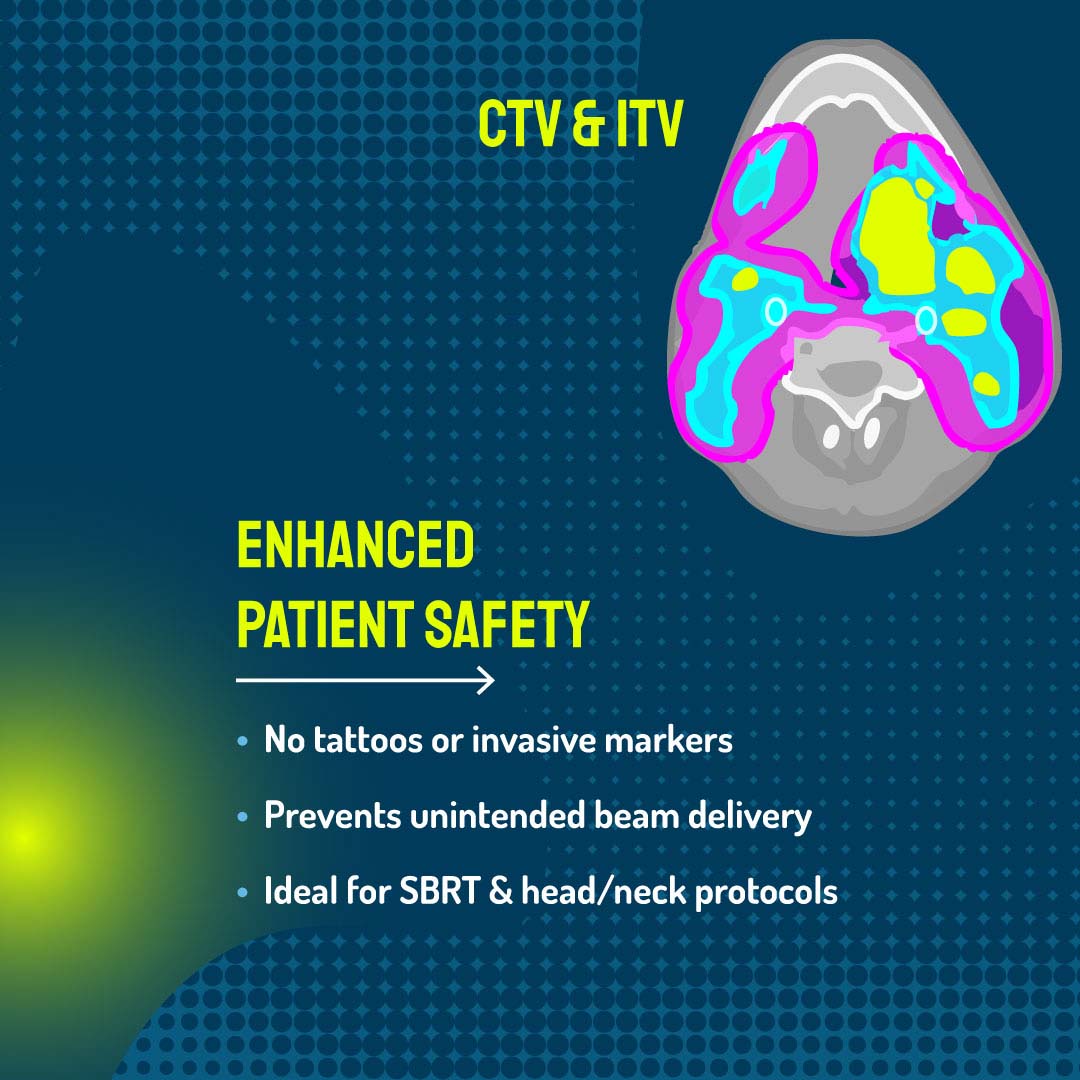

In motion-sensitive treatments such as SBRT or head-and-neck protocols, every millimeter – and every movement – matters. The RPS SGRT platform is designed to deliver frameless precision through seamless integration with modern surface-guided radiotherapy (SGRT) systems. By enabling real-time monitoring and live intrafraction motion correction, it enhances both safety and treatment accuracy.

Built specifically for surface scanner workflows, RPS SGRT is API-ready, compatible with major OEM systems, and supports fully frameless and adaptive radiotherapy approaches. During treatment, the system continuously tracks the patient’s surface and automatically compensates for deviations with ±3° angular correction, reducing the need for unnecessary imaging or repositioning.

The platform improves safety by preventing unintended beam delivery without tattoos, masks, or invasive markers. With intuitive operation, quick installation, and compatibility with standard indexing systems, it fits naturally into daily clinical routines while maintaining data continuity for adaptive workflows.

The result: a smarter, safer, and more precise SGRT experience for both clinicians and patients.

RPS base: Sub-Degree Precision for Modern Image-Guided Radiotherapy

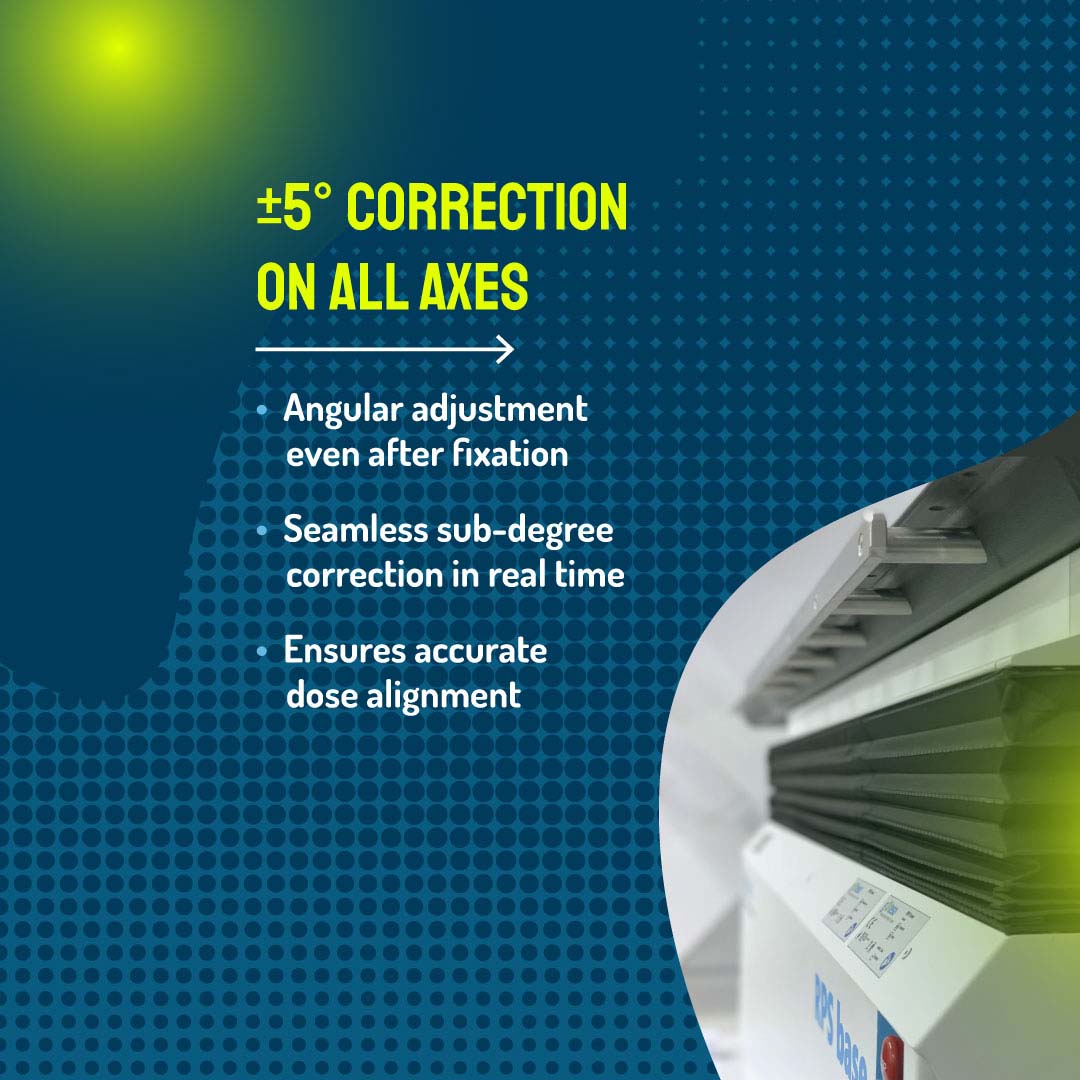

When treating highly sensitive targets such as the brain, even the smallest deviation can impact clinical outcomes. The RPS base is engineered to deliver real-time 6DoF corrections during IGRT, enabling sub-degree alignment both before and throughout the treatment session. With an angular correction capability of ±5° across all axes, it supports accurate dose delivery even under demanding conditions.

Clinically, the system is optimized for SBRT, SGRT, and daily IGRT, making it especially suited for cranial applications and mask-free positioning workflows. Its precision helps reduce penumbra, increase reproducibility, and improve overall treatment consistency in fractionated and stereotactic protocols.

Designed for everyday use in radiotherapy departments, the RPS base integrates seamlessly into established workflows. It is compatible with carbon baseplates, features a low table height for patient comfort, and offers API readiness for Linac system integration.

With adaptive-ready architecture, the RPS base is built to meet the evolving demands of high-precision radiotherapy centers – today and in the future.

Radiotherapy Positioning Systems Built for Integration

Modern radiotherapy needs positioning systems that adapt to many clinical workflows. Our RPS product line follows this modular approach and supports a wide range of treatment setups. The systems work in cranial applications, full body treatments and MR guided workflows. Each platform combines clinical accuracy, easy integration and clear motion control with minimal room requirements.

The RPS line supports SGRT workflows, MR Linac environments and fixed beam configurations. The systems run stable under daily load and follow defined positioning paths without drift. More than 2000 installations worldwide show how the platforms work in many clinical environments and OEM integration projects.

The design focuses on fast mechanical response, clean motion control and predictable positioning behavior. This helps during conformal dose delivery and supports radiotherapy teams that need reliable patient setups for photon treatments. OEMs use the systems as a base for complete radiotherapy components and build their therapy workflows around the motion platform.

The RPS portfolio covers compact tables for cranial work, large platforms for body treatments and systems that operate inside MR fields. Each model follows the same control logic which keeps integration work short and supports a consistent user experience.

If you plan new radiotherapy solutions with clear positioning control and flexible integration paths, the RPS line gives you a proven base for development and clinical use.

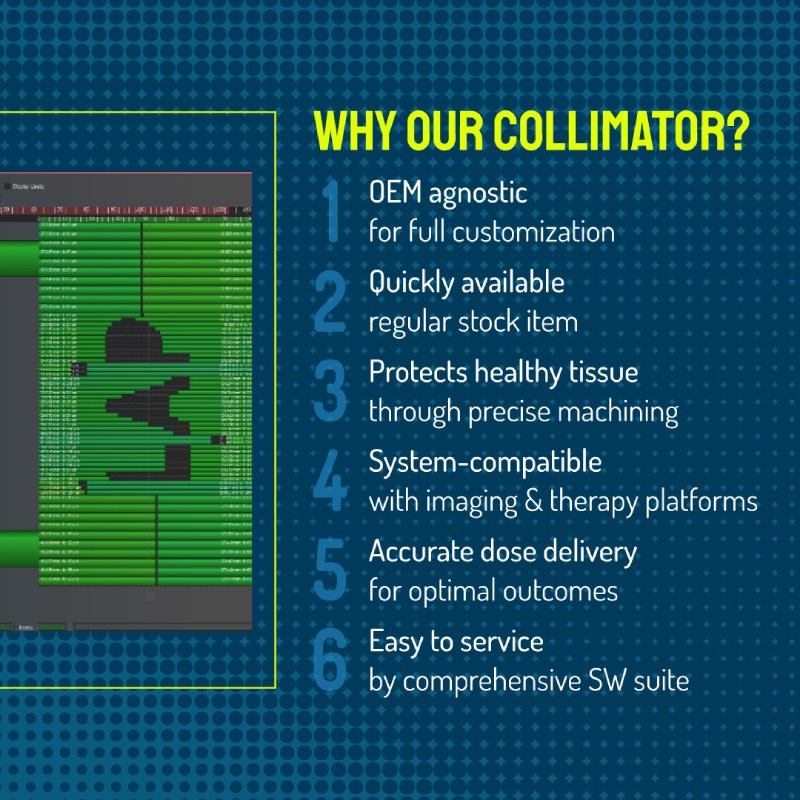

Beyond One MLC: Tailored Multileaf Collimator Designs for Every Radiotherapy Application

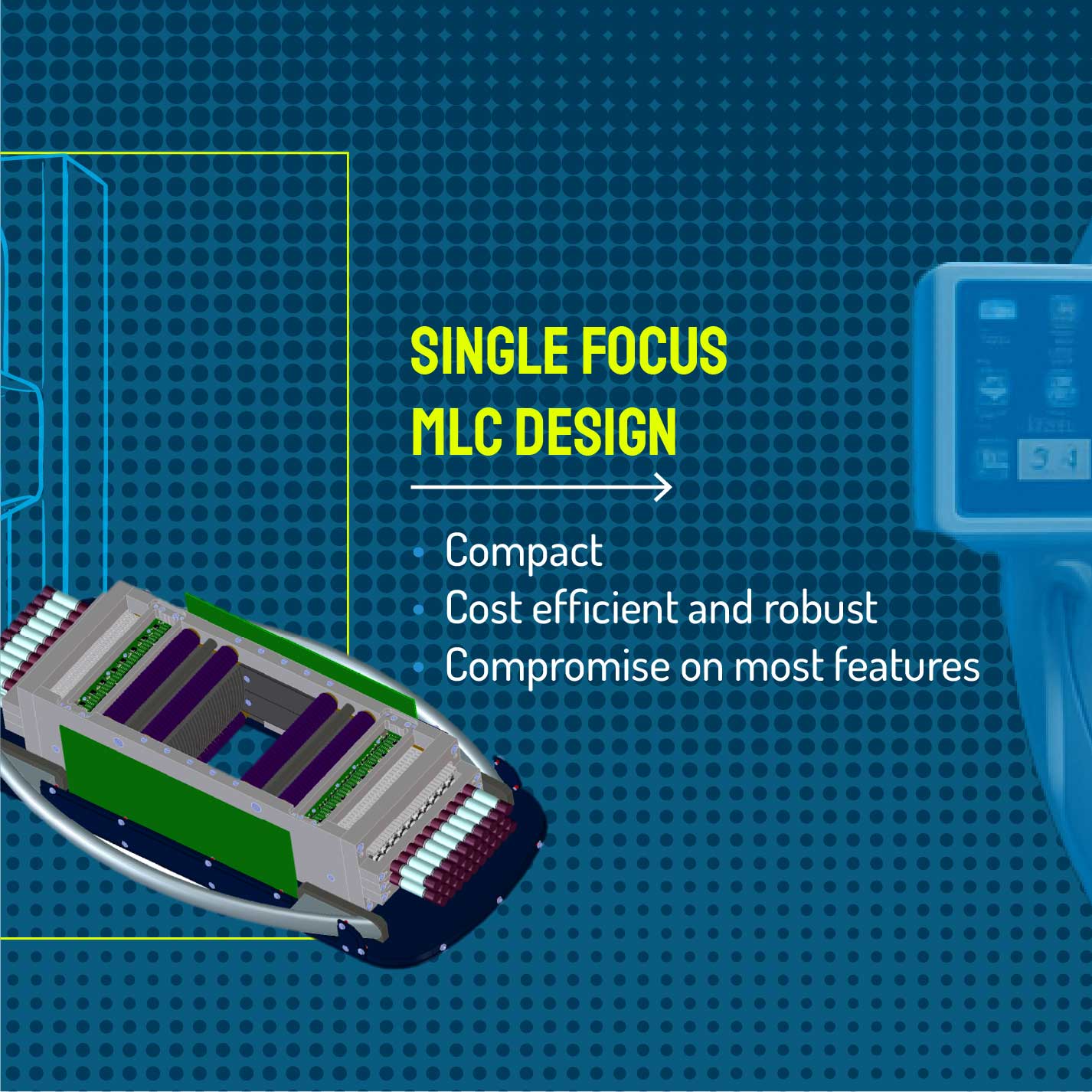

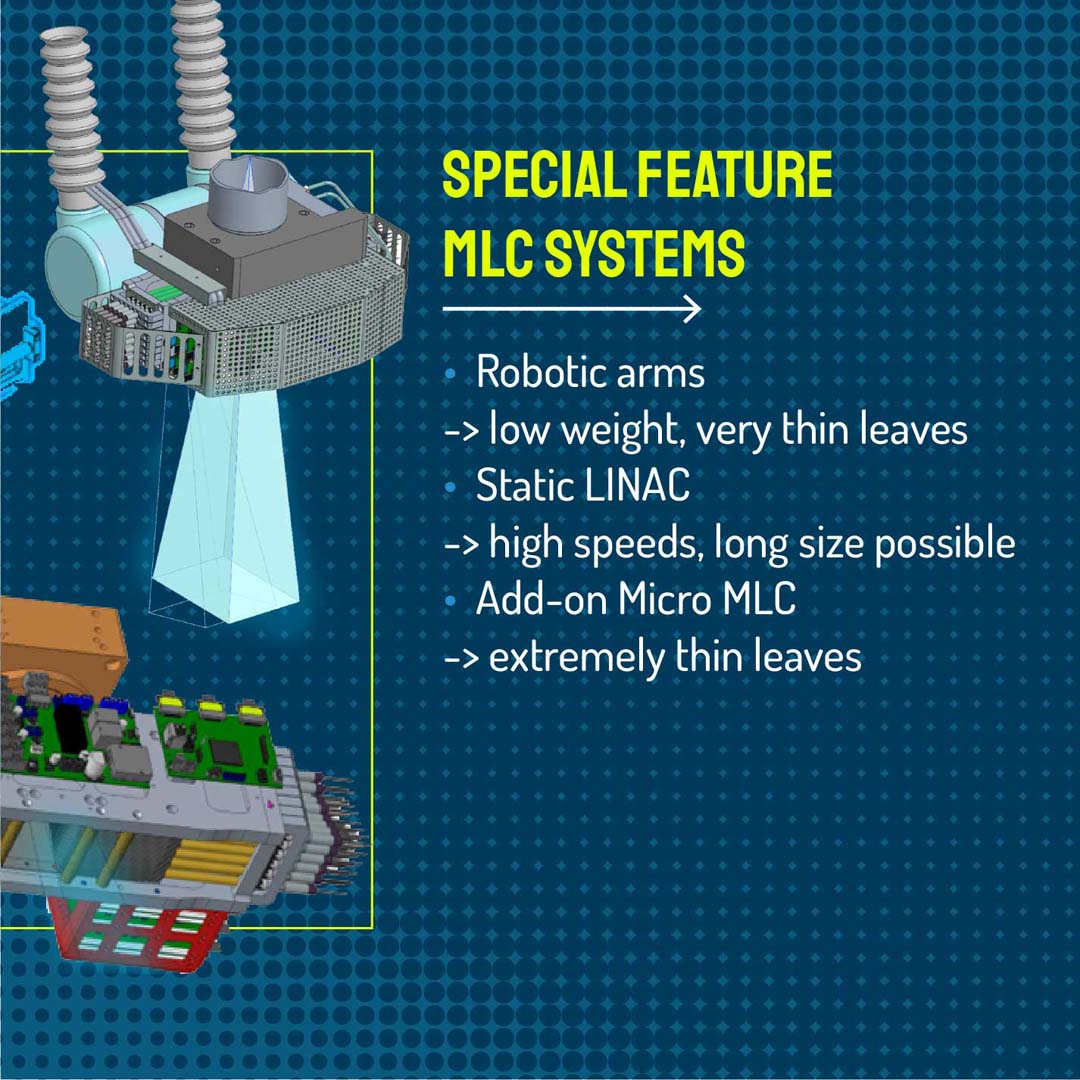

Radiotherapy is not one-size-fits-all and neither are multileaf collimators. At gKteso, we develop a full range of MLC designs engineered for different OEM requirements, workflows, and clinical environments. What may look similar on the outside represents highly specialized architectures optimized for cost, performance, or advanced beam-shaping precision.

Our portfolio spans single-focus MLCs for compact, cost-efficient setups; double-focus designs offering near-ideal field edges and penumbra performance; and electron or Co-60 MLCs built with optimized leaf materials for pragmatic, high-impact clinical use. Special-feature variants – such as robotic-arm MLCs, micro-MLCs, or LINAC-optimized high-speed versions – address unique use cases in research and precision therapy.

To support seamless integration, we also provide custom housings, EMC-shielded structures, OEM-specific interfaces, and accessory mounting options. From feasibility studies to high-speed control technology and architectural consulting, we guide OEM engineering teams through every step of the development process.

The result: MLC systems precisely matched to your platform, ready for research or clinical deployment.

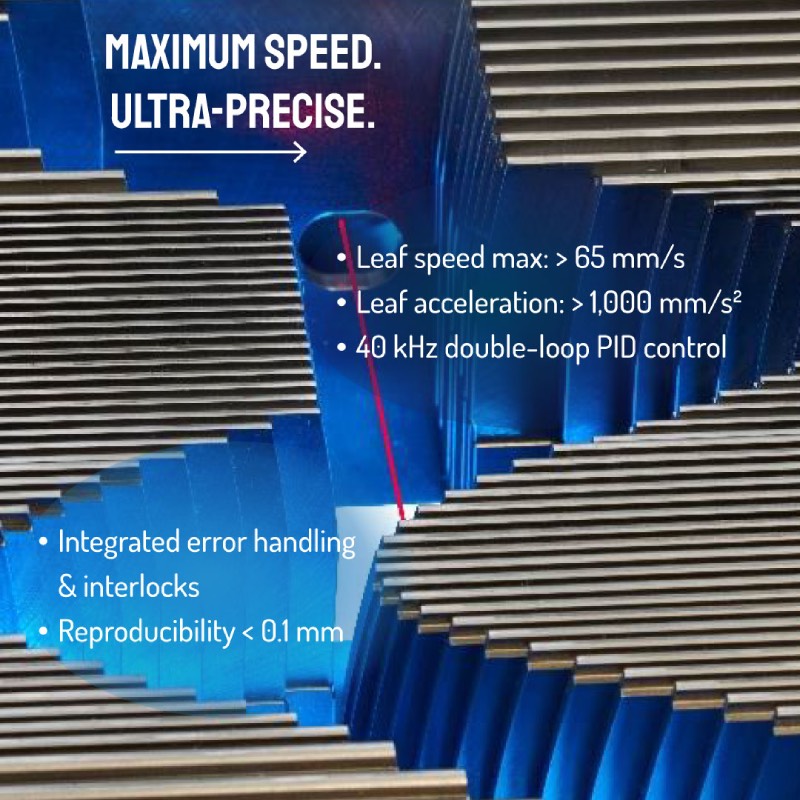

From Mechanics to Motion Intelligence: Dynamic Control for Advanced MLC Systems

High-performance MLC systems require more than mechanical precision – they rely on intelligent motion control that delivers speed, stability, and perfect synchronization in real time. That’s why we developed our Dynamic Control Concept, a complete architecture designed to drive high-speed leaf motion with sub-millimeter accuracy and seamless OEM integration.

At the core of this approach is a high-frequency, double-loop PID controller running at 40 kHz, enabling precise control even at extreme accelerations. With leaf speeds above 165 mm/s, leaf acceleration above 1,000 mm/s², and guide acceleration exceeding 10,000 mm/s², the system supports the demands of dynamic treatment plans, IMRT, VMAT, and next-generation beam-shaping strategies.

Accuracy of approximately 0.1 mm, combined with real-time Ethernet communication and integrated safety mechanisms, ensures predictable performance across all motion phases.

From modular hardware to synchronized timestamps and preloading capabilities, our Dynamic Control Concept transforms mechanical movement into motion intelligence – empowering OEMs to push radiotherapy precision even further.

Multileaf Collimator for Precise Radiotherapy Beam Shaping

Our multileaf collimator gives radiotherapy systems a stable base for field aperture control and conformal dose delivery. The device works as a standard MLC for LINAC platforms and supports beam shaping for photon therapy, VMAT and SRS.

The collimator uses 120 leaf pairs for a 40 mal 40 cm field. Inner leaves measure 40 mal 5 mm, outer leaves 2 mal 10 mm. The system reaches an overtravel of 101 % and a bank motion of 272.7 mm. The leaf height measures 80 mm and the complete unit weighs about 125 kg.

The motion hardware reaches leaf speeds above 65 mm pro Sekunde and accelerations above 1000 mm pro Quadratsekunde. A 40 kHz PID control loop holds the leaf path inside a tolerance below 0.1 mm. Integrated interlocks and error handling protect the beam limiting device during clinical operation.

An SDK for Windows und Linux, a complete MLC emulator and a service GUI support fast integration. Remote access and update functions shorten development and service tasks for OEMs and research teams.

This standard beam shaping device fits LINAC integration projects that need compact radiotherapy hardware with exact field control. The machined leaf geometry shapes the photon beam and protects healthy tissue through accurate dose distribution.

From Early Concepts to High-Performance Systems: The Evolution of Our MLC Technology

Over the past three decades, our engineering teams have developed a wide spectrum of multileaf collimators (MLCs) – each tailored to specific clinical needs, OEM architectures, and treatment technologies. From early photon and electron therapy applications to today’s high-performance MLCs integrated into advanced MRI-guided systems, every generation has pushed the limits of precision and motion control.

What began with foundational mechanical designs has evolved into sophisticated beam-shaping platforms characterized by high-precision mechanics, intelligent motion control, and seamless system integration. Along the way, each model addressed different challenges: compact MLCs for cost-sensitive setups, double-focus systems for superior penumbra performance, specialized variants for research environments, and fully motorized solutions for serial OEM production.

This journey illustrates an important truth about medtech innovation: progress is rarely linear. Instead, it adapts to purpose, clinical context, and integration needs.

Explore our MLC evolution proof that tailored engineering delivers meaningful impact in radiotherapy.