Contract Manufacturing

From complex concept to market-ready product.

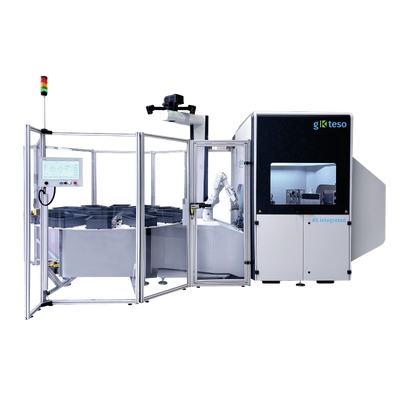

Transform complex medical technology ideas into high-quality, production-ready products. With gKteso Contract Manufacturing, OEMs gain end-to-end manufacturing expertise – from engineering transfer and prototyping to validated series production and scalable supply. Our specialists ensure robust processes, precision manufacturing, and consistent quality that integrates seamlessly into clinical environments. The result: faster time to market and reliable product performance backed by proven production excellence.

| Scope | Details |

|---|---|

| Quality Standards | ISO 13485 certified, MDR and FDA 21 CFR Part 11 compliant |

| Production Range | From prototype to high-volume serial production |

| Technical Scope | Mechanical, electronic, and firmware integration |

| Regulatory Support | Full CE documentation, traceability, and risk management |

Why Conventional Manufacturing Falls Short in MedTech

Medical device OEMs face increasing complexity, strict regulatory requirements, and pressure to accelerate time-to-market. Standard contract manufacturers often lack the integration capability, documentation discipline, and technical depth required for modern MedTech systems.

Limited Flexibility

Traditional manufacturers are optimized for repeat production, not for transitioning prototypes into compliant serial builds.

Incomplete Regulatory Support

Missing documentation or insufficient traceability can delay CE/FDA approval and increase project risk.

Technology Gaps

Many facilities cannot handle radiation-hard, MR-safe materials or mixed mechanical-electronic assemblies for advanced medical systems.

Scaling Challenges

Unaligned processes lead to long transfer times and inconsistent product quality during scale-up.

Advantages and Benefits

Contract Manufacturing for MedTech OEMs bridges these gaps.

We combine precision engineering, regulatory compliance, and production scalability – all under one ISO 13485–certified roof.

From design transfer to validated series manufacturing, we deliver consistent, compliant, and repeatable quality.

- End-to-end support from prototype (1-5 units p.a.) to serial production (5000 units p.a.)

- ISO 13485 and MDR/FDA readiness for global market access

- Radiation-hard, MR-safe materials and semi-automated assembly

- Digital process validation and full traceability

- Integration of mechanical, electronic, and firmware components

- Risk-managed workflows and CE documentation packages

How You Benefit

End-to-End Manufacturing Expertise

From early design transfer to validated series production – ensuring seamless transition, reduced risk, and reliable product performance for medical device OEMs.

Regulatory Compliance & Quality Assurance

ISO 13485 certified processes with full MDR and FDA readiness, complete traceability, and documented validation for faster market approval and long-term compliance confidence.

High-Precision Engineering

Advanced CNC machining, Radiation-hard, MR-safe materials and processes, semi-automized assembly to achieve extreme accuracy, reproducibility, and stability in complex MedTech components and systems

Scalable Production Capacity

Flexible manufacturing setup for small pilot runs, rising production volumes from five to several thousand units per year or even automated high-volume production, supporting efficient ramp-up and secure supply chain integration.

Get in Touch

Bring Your Medtech Product Vision to Life

Contact us to learn how Contract Manufacturing turns your MedTech innovations into certified, scalable products: from design transfer and prototyping to global CE/FDA-compliant production.

- From concept transfer and precision prototyping to CE/FDA-compliant series production

- Smooth integration with your development, regulatory, and supply chain processes

- 35+ years of proven expertise in medical technology and high-precision systems

Seamless Integration

into MedTech and OEM Production Workflows

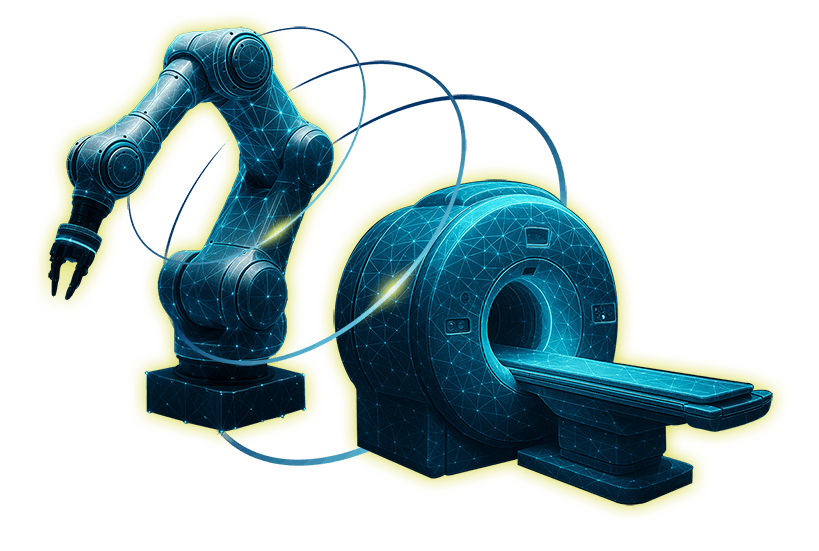

Our digital production environment connects engineering, manufacturing, and validation seamlessly. We manage data traceability, risk analysis, and CE/FDA documentation in one controlled workflow. Radiation-hard and MR-safe production capabilities ensure compatibility with sensitive imaging and therapeutic systems.

Every manufacturing cell is validated according to IQ/OQ/PQ protocols and monitored through serial number tracking, ensuring reproducibility across the entire device lifecycle.

Our Applications

for MedTech and High-Performance OEM Systems

Reliable, compliant, and scalable – our contract manufacturing services support a wide range of applications:

- Medical imaging and diagnostic systems

- Surgical and microsurgical devices

- Radiotherapy and patient positioning systems

- Mechatronic and robotic MedTech components

- MRI- and radiation-compatible subassemblies

- Prototype-to-series transitions for regulated industries

Manufacturing Excellence

Precision Engineering

Regulatory Compliance

Radiation-hard, MR-safe products

Time-to-Market Acceleration

Global Scalability

Learn more about our product development services for OEMs

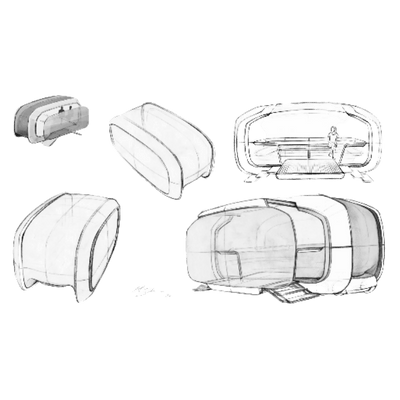

Discover how gKteso Design as a Service supports MedTech innovation: from digital concept to production-ready systems. Our teams deliver user-centered industrial design, engineering integration, and full CE/FDA documentation to accelerate certification and market launch.

Learn more about …

Turning complexity into Clarity – with gKteso’s Design as a Service

Learn more about …

Patient Positioning Systems by gKteso: Tailored for modern radiotherapy environments.

Schedule an appointment now!

Frequently Asked Questions

Can you support both prototypes and large-scale production?

Yes. We offer flexible manufacturing capacity – from rapid prototypes, small production volumes for ramp-up periods with 1-5 or 10 units p.a. for design validation to fully validated high-volume production of 5.000 or more units per year, ensuring smooth scaling as your product grows.

Which quality and regulatory standards do you follow?

Our processes are fully ISO 13485 certified and support EU MDR 2017/745 and FDA 21 CFR Part 11 compliance. We provide complete documentation, risk management, and full traceability.

Can you work with requirements under keV and MeV Radiation or MR-safe conditions?

Yes. We daily work with Radiation-hard, MR-safe architectures, materials, coatings and ahesives to assemble sensitive devices and ensure compliance with MedTech safety requirements.

How do you guarantee product consistency and reliability?

We use validated processes, digital production control, serial number tracking, and in-line quality checks to maintain reproducibility and performance throughout the production cycle.

Can you support global market access and certifications?

Absolutely. We prepare regulatory-ready documentation and help accelerate CE marking in Europe under MDR and FDA clearance in the U.S., enabling faster worldwide market entry.

Explore advanced OEM product development with gKteso Design as a Service

Design as a Service

For OEMs, R&D leaders, and system architects, our Design as a Service (DaaS) supports the entire product journey: user-focused industrial design, mechanical and electrical integration, risk management, and documentation for regulatory approval. Ready for seamless OEM integration, scalable manufacturing, and fast global deployment.

Customized MLC

Tailored for OEMs, research centers, and novel radiotherapy platforms, our customized MLCs are co-developed to meet unique geometric, electronic, or integration needs. We support you from CAD concept to validated hardware, whether for FLASH, MRI-based therapy, compact systems, or proton beamlines.

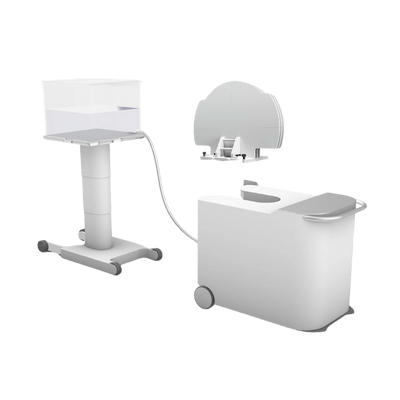

Customized OEM QA tools

Customized OEM QA Phantoms and Water Phantom Transport Units from gKteso provide tailored solutions for commissioning, routine QA, imaging calibration, and OEM system integration. With reproducible precision, MDR/FDA compliance, MR compatible options and scalable manufacturing, they ensure reliability in clinical and research environments worldwide.