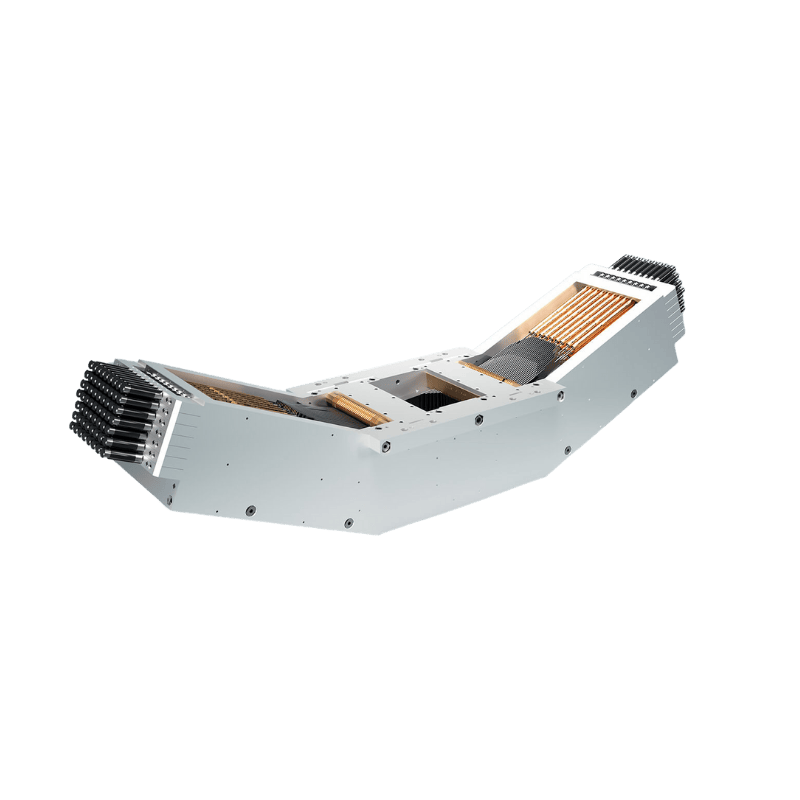

Bespoke MLC systems

for advanced integration

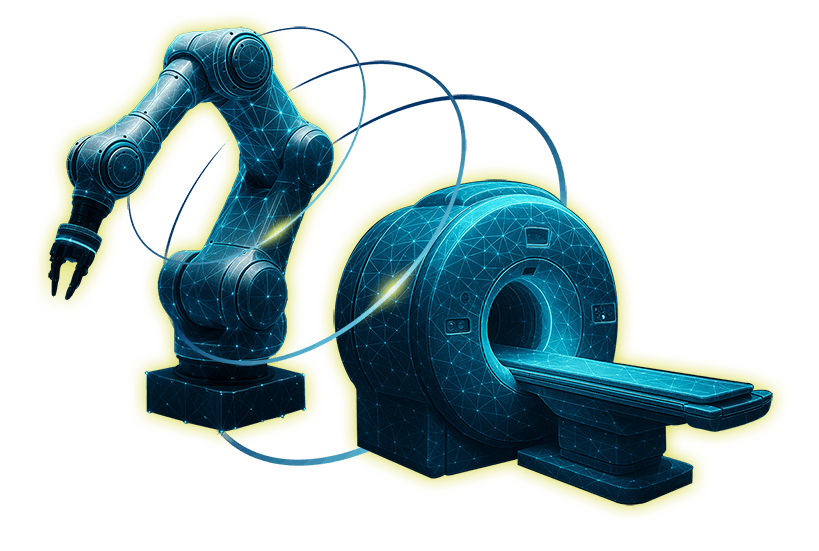

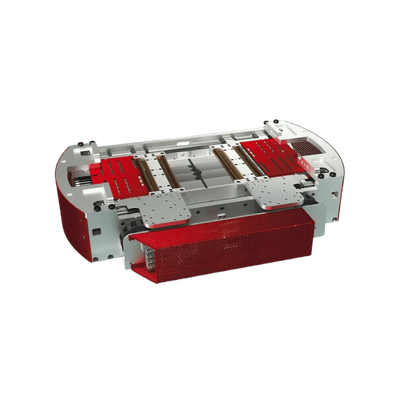

Developed in close collaboration with OEM partners, our customized MLCs are engineered to meet unique clinical and technical needs. From robotic Radiosurgery systems, FLASH applications to MRI-compatible high-speed variants – each design is tailored for maximum precision, seamless integration and advanced treatment workflows.

Leaf Configuration

- Single focus and double focus designs

- Variable leaf thickness & micro-leaf geometry

- 80 to 160 or more leaves for high-resolution shaping

- Micro MLC modules with ultra-thin leaves

Actuation & Motor Design

- Piezo-driven actuators for ultrafast motion

- Space optimized motor-based drive systems

- Dual-layer configurations for advanced modulation

- High-speed motion (> 10 cm/s) for 4D and gated therapies

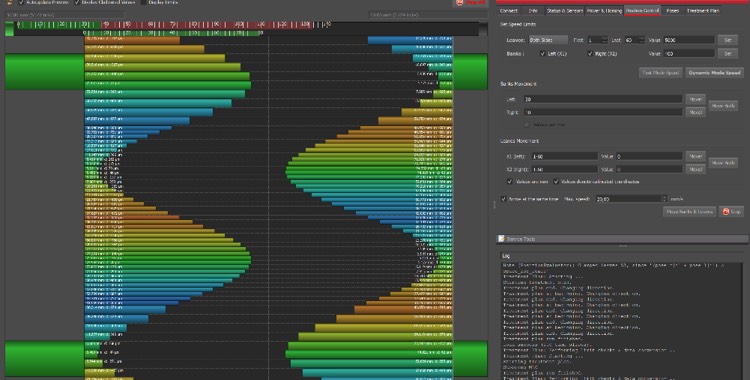

Control & Interface Options

- Motion control with submillimeter precision (<0.1 mm)

- Touchless ultra-precise (<10 microns) secondary sensors

- OEM-specific mechanical & software interfaces

- Static LINAC or robotic integration setups

Materials & Durability

- MR-compatible, low-EM, non-magnetic components

- Leaf material & height optimization for photons, electrons, protons, and Co-60 γ-radiation

- EMC-shielded housings and cabling

- Robust designs engineered for long lifecycle performance

Why Conventional Collimators Fall Short in Next-Gen Radiotherapy

Emerging treatment technologies like adaptive, MRI-guided, and proton radiotherapy demand performance beyond standard MLC systems. Conventional collimators often lack the speed, customization, and electromagnetic compatibility required for these workflows.

Limited Customization

Fixed geometries and mechanical constraints restrict OEM design flexibility for new beamline concepts.

Incompatibility with MR Systems

Standard MLCs contain ferromagnetic materials both in the tungsten alloy and in the frame that interfere with MRI-based guidance and hybrid imaging systems.

Slow or Inflexible Motion

Traditional motor drives cannot deliver the submillisecond response or motion profiles required for gated or 4D treatments.

Integration Barriers

Closed interfaces complicate system development, limiting synchronization with robotic arms or adaptive planning software.

Advantages and Benefits

Our customized MLC designs remove these barriers with modular engineering, piezo-motion technology, and full MR compatibility. Developed and manufactured in Germany, each system is co-engineered with OEM partners for seamless integration into advanced radiotherapy platforms.

- Dual-focus and micro-leaf geometry for high-resolution beam control

- Piezo-driven actuation for ultrafast motion and submillimeter precision

- MR-compatible, non-magnetic materials for hybrid imaging architectures

- Open mechanical and software interfaces for robotic and adaptive setups

- Modular system architecture scalable from compact to large-field MLCs

- Delivered with ISO 13485 certification and CE/FDA documentation support

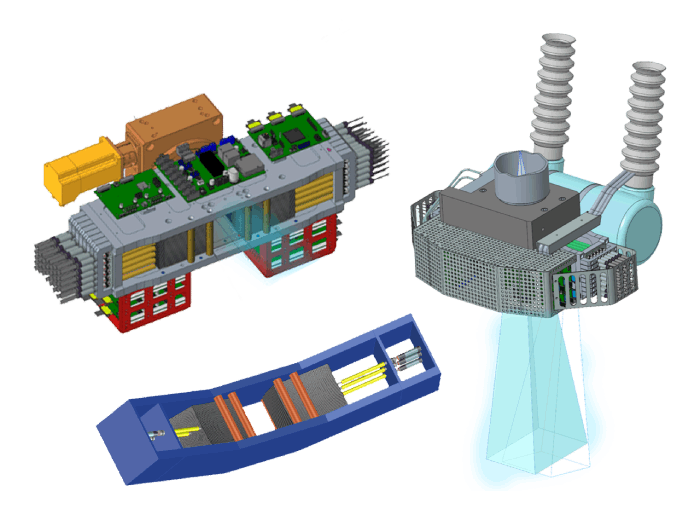

Application-Specific Engineering

Each MLC is developed for its intended therapy type – from dual-layer arc systems to micro-leaf modules for stereotactic and MRI-guided treatments. Designs are optimized for geometry, motion range, and beam characteristics.

Collaborative OEM Development

We co-engineer with OEM partners through CAD/CAM exchange, rapid prototyping, and on-site validation. Firmware and API customization ensure seamless hardware and software integration.

Safety and Regulatory Assurance

All systems are prepared for CE and FDA submissions, including IEC 60601-1, 60601-2-1 , ISO 14971 risk documentation and verified interlock mechanisms for treatment safety and compliance.

Reliable Long-Term Performance

Built with robust mechanics, MR-safe materials, and verified motion control, our collimators deliver consistent operation and low maintenance across the full product lifecycle.

Get in Touch

Co-Develop Your Bespoke Collimator with gKteso

Contact us to learn how to integrate our customized MLC designs for ultrafast, adaptive beam shaping, MR-compatible operation, and seamless OEM system integration across advanced radiotherapy and research platforms.

- Tailored leaf geometries and motor control for R&D or OEM series

- Adaptive-ready, MRI-compatible, and proton therapy options

- Full lifecycle support: from design validation to integration

Seamless Integration

into Adaptive and Robotic Workflows

Our customized MLC designs connect directly to robotic, C-arm, Ring-based or static LINAC systems through open control architectures. With Ethernet or custom API interfaces, it synchronizes beam logic, gating, and feedback loops for complex treatment scenarios.

Fully compliant with EU MDR 2017/745, the system’s low-EM construction ensures compatibility with MRI-guided workflows and particle therapy gantries. Each configuration undergoes electromagnetic validation and life-cycle testing for OEM deployment and long-term reliability.

Our Applications

for Adaptive, MRI-Guided, and Proton Therapy Systems

Flexible, fast, and co-engineered for precision: our customized MLC designs support diverse advanced radiotherapy applications:

- Adaptive radiotherapy with 4D dose modulation

- FLASH and motion-managed therapy research

- MRI-Linac and hybrid imaging systems

- Robotic MLC integration for compact treatment units

- Proton and Co-60 beam shaping

- Small-animal and preclinical research setups

Adaptive Radiotherapy

MRI-Compatible Systems

Robotic Integration

Proton Beam Therapy

Stereotactic Radiosurgery

OEM Custom Design

Learn more about our beam-shaping innovations for OEM partners

Discover how gKteso’s customized MLCs enable MR-compatible, adaptive, and particle-based radiotherapy systems. From concept to certified integration, our engineers deliver scalable, high-performance collimator solutions for research centers and OEM development teams worldwide.

Schedule an appointment now!

Frequently Asked Questions

What customization options does gKteso offer for multileaf collimators?

We offer fully tailored MLCs for adaptive radiotherapy, proton therapy, and compact or MRI-guided LINAC systems. Options include variable leaf thicknesses, robotic integration, dual-layer configurations, and narrow-leaf designs for stereotactic applications. Our portfolio spans from 80 up to more than 160 leaves.

Can your custom MLCs be integrated into MRI-compatible systems?

Yes. We developed and built several designs of MR-compatible multileaf collimators with low-EM designs, non-magnetic components, and radiation-shielded cabling – ideal for MRI-Linac and hybrid imaging-guided systems.

How fast can the leaves move in your robotic or micro-MLCs?

Depending on configuration, our leaf motion systems enable speeds up to 10 cm/s with <0.1 mm micropositioning – supporting 4D, gated, or motion-managed radiotherapy protocols.

What services do you provide to OEMs developing new radiotherapy platforms?

We support full co-development workflows, including CAD file exchange, on-site testing, firmware customization, and CE/FDA documentation. Our engineering team collaborates closely with OEMs throughout the design and integration lifecycle.

Can your MLC technology be adapted for emerging radiotherapy modalities?

Yes. Our modular architecture allows adaptation for FLASH, electrons, protons, and other novel modalities. By combining piezo-driven precision, touchless sensing, and scalable leaf configurations, we can tailor the system’s footprint, speed, and beam-shaping performance to match unique research or clinical requirements – whether ultra-compact for robotic systems or high-power for large-field treatments.

Explore more advanced beam-shaping solutions for radiotherapy

Standard MLC

Our gold-standard 40×40 cm 120 leaf MLCs are developed for high-precision beam shaping in conventional LINAC systems. With optimized tungsten leaf geometry, fast-response actuators, and low-penumbra performance, these units support advanced treatment protocols like IMRT, VMAT, and SRS.

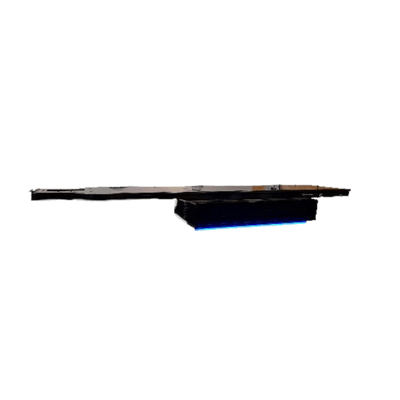

RPS Base

The RPS Base offers full 6DoF surface-guided control for advanced radiotherapy workflows. It enables ±5° angular correction across all axes, ensuring exact isocenter alignment for every session. With its smart, Linac-ready design, it streamlines setup, improves reproducibility, and supports adaptive treatment strategies.

RPS Proton / BNCT Fixed Beam

The RPS Fixed Beam delivers robotic flexibility for fixed-beam proton, other particle or BNCT therapy centers. It ensures precise, reproducible positioning for both supine and seated treatments while maintaining constant isocenter geometry. Designed for cost-effective integration, it reduces infrastructure requirements and supports advanced radiotherapy workflows without a rotating gantry.