Customized QA Tools

for High-Precision Radiotherapy & Imaging

Customized QA tool from gKteso combine OEM-specific design with high-precision Solid Water (RW3) materials to ensure accurate and reproducible results in radiotherapy and imaging. Each phantom is developed for seamless integration into next-generation systems, from prototype to serial production. With full CE/MDR and FDA ready documentation, these customized solutions deliver lasting reliability for QA, calibration, and clinical validation worldwide.

OEM design & scalable production

for medical QA systems

High-precision RW3 & radiation-hard materials

for QA reliability

Custom geometries

for LINAC, proton

& imaging QA

CE/MDR & FDA-ready

for global OEM integration

Why Custom QA Tools Matter in Radiotherapy

Standard QA systems often cannot match the complexity of OEM platforms. Custom geometries, integration requirements, and radiation-hard materials are essential for accurate beam validation and long-term stability. These tools fill the gap between prototype and production – ensuring quality assurance, calibration, and reproducibility across global systems.

OEM Integration Challenges

Radiation therapy platforms differ in geometry, detector setup, and workflow. Without custom phantoms, precise validation and calibration are difficult to achieve.

Regulatory Requirements

MDR and FDA compliance demand documentation consistency from R&D to clinical deployment. OEM-ready QA tools streamline this process.

Long-Term Stability

Radiation exposure, handling, and transport can degrade non-specialized materials. RW3 Solid Water and radiation-hard polymers, adhesives and other materials guarantee dimensional, visual and dosimetric stability over years.

Workflow Efficiency

Manual QA setups often slow down system commissioning and daily validation. Customized QA tools simplify detector alignment, automate measurement routines, and reduce setup time, enabling faster and more consistent QA across all treatment platforms.

Advantages and Benefits

Customized OEM QA Tools address these challenges with precise, reproducible geometries, radiation-hard materials, and long-term dimensional stability. Each phantom is developed and verified under ISO 13485 development standards to ensure consistent QA performance from prototype to clinical deployment. Full CE/MDR and FDA ready documentation guarantees regulatory confidence for OEM integration and international use.

- OEM-specific design and scalable manufacturing for QA, calibration, and R&D

- Tissue-equivalent Solid Water (RW3) for reproducible dose measurement

- Exclusive designs for OEMs, marketed and labeled under their registration

- Mechanical precision down to 0.02 mm

- Short development cycles through local manufacturing and rapid prototyping from 1 or 5 to several hundred units per year

How You Benefit

Tailored OEM Design

Each phantom is engineered to match system geometry, detector configuration, and workflow - ensuring perfect integration into next-generation radiotherapy and imaging platforms.

Verified Precision Materials

Solid Water (RW3) and radiation-hard polymers guarantee reproducible performance for dosimetry, calibration, and long-term QA stability.

Regulatory-Ready Integration

All QA tools are fully CE/MDR ready, and documented for seamless regulatory approval and global clinical deployment.

Our Comprehensive QA Solutions

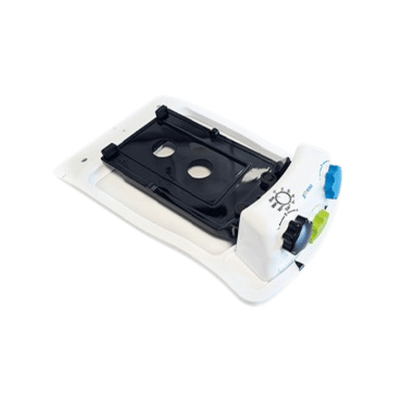

Customized OEM QA Tools for Radiotherapy & Imaging

Customized OEM QA Tools from gKteso are engineered for radiotherapy QA, calibration, and imaging validation. Each system is tailored to OEM requirements and manufactured with Solid Water (RW3) and radiation-hard materials for reproducible, long-term accuracy. These phantoms integrate seamlessly into LINAC commissioning, proton therapy, and advanced imaging systems, providing complete QA reliability from prototype to clinical deployment.

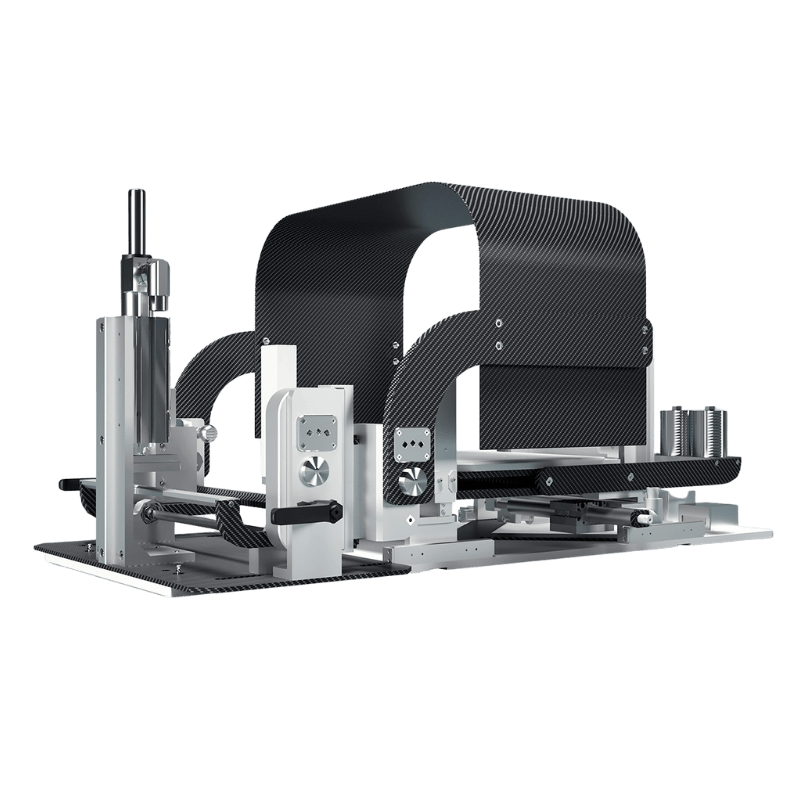

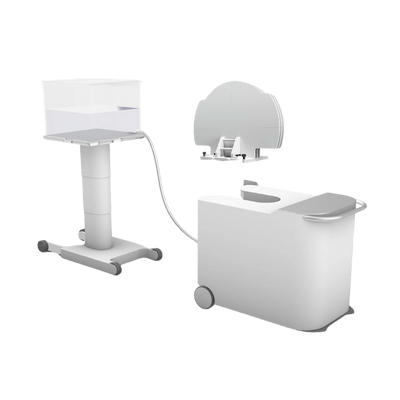

Water Phantom Transport Units

Water Phantom Transport Units from gKteso ensure safe mobility and long-term stability for QA systems and water phantoms. Designed for OEMs and clinical users, they combine robust PMMA construction with precision mechanics for reproducible measurements during transport, commissioning, and QA testing. MR compatible options, web-based software and intuitive interfaces simplify setup, tracking, and documentation.

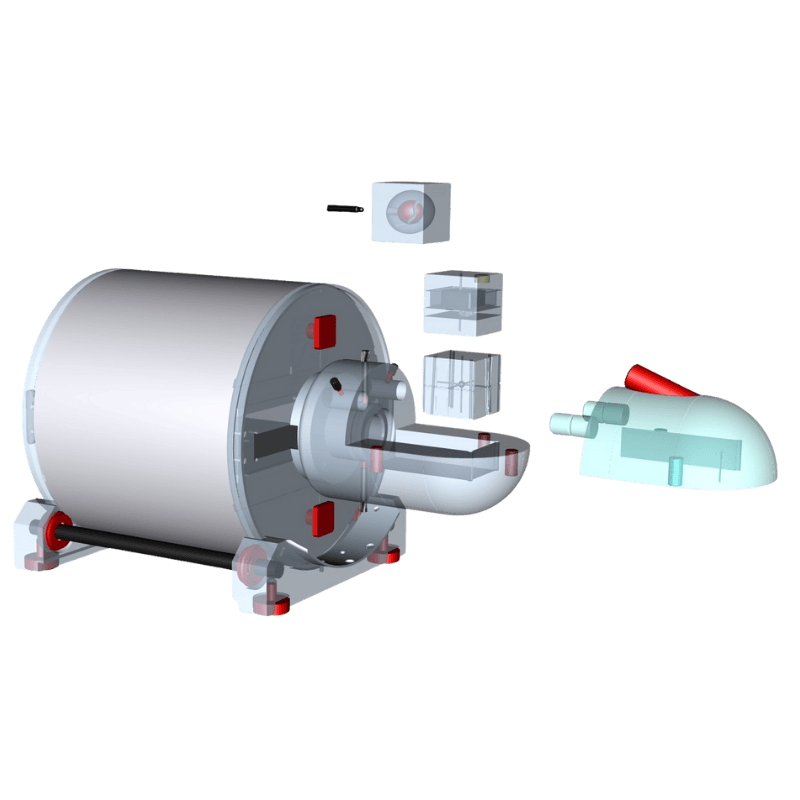

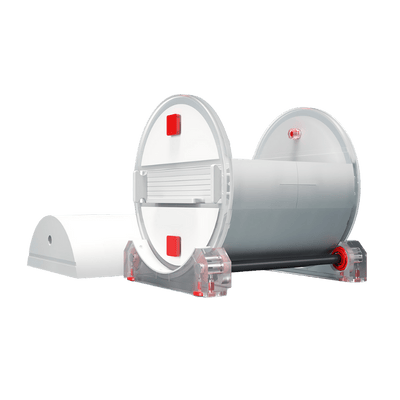

MR Distortion Phantom

The MR Distortion Phantom is designed for geometric accuracy verification and laser alignment QA in MRI-based radiotherapy. Made from MR-safe, non-ferromagnetic materials, it detects geometric distortions and ensures image consistency across MR-Linac and diagnostic systems. Its modular structure supports customizable setups for OEM and clinical QA. Easy to handle by one person and modular scale from 1 to 3 slabs up to full size volumes at easy.

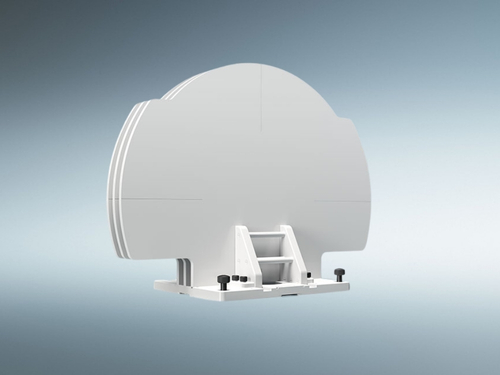

LASER – MR - Alignment Phantom

The LASER – MR – Alignment Phantom ensures precise laser alignment and MR isocenter verification. It provides an independent method for checking alignment between imaging planes and laser planes while detecting gantry rotation and couch deflection. Built for MR environments up to 3T, it simplifies MR QA routines and improves workflow consistency.

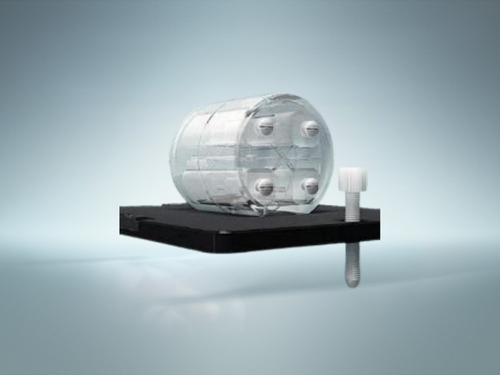

Anthropomorphic Head Phantom

The Anthropomorphic Head Phantom replicates human head anatomy for realistic radiotherapy QA and end-to-end testing. Its internal structure includes RW3 solid water, bone-equivalent plates, and muscle-equivalent inserts. Designed for use with immobilization masks, it supports SGRT calibration, imaging validation, and OEM development.

Technical Comparison - Customized OEM QA Tools and Phantoms

| Feature | Customized OEM QA Tools | Water Phantom Transport Units | MR Distortion Phantom | MR LASER Alignment Phantom | Anthropomorphic Head Phantom |

|---|---|---|---|---|---|

| Material | Solid Water (RW3), PMMA, radiation hard composites | PMMA water basin, aluminum frame | Non ferromagnetic MR safe materials | PMMA and CuSO₄ solution (0.1 percent) | RW3 solid water, bone and muscle equivalents |

| Dimensions | OEM specific geometry | Custom dimensions per system | 666 × 486 × 100 mm plates | 147.4 × 152.4 mm measuring unit | Human head equivalent, mask compatible |

| Weight | Varies by design | Approx. 20 to 40 kg | 15.5 kg (3D), 45.3 kg (3D max) | 8.16 kg total | Approx. 5 to 8 kg |

| Accuracy | ±0.25 mm positioning precision | ±0.25 mm mechanical accuracy | MR distortion accuracy smaller 0.5 mm | Laser alignment within 0.3 mm | Setup reproducibility smaller 1 mm |

| Applications | OEM QA, commissioning, RnD | Beam model validation, QA mobility | MR distortion, MR Linac commissioning | MR laser alignment QA | SGRT, imaging validation, workflow QA |

| Compliance | ISO 13485, CE MDR, FDA ready | CE MDR, FDA ready | MR conditional up to 3T | MR conditional up to 3T | CE MDR compliant, OEM ready |

Get in Touch

Integrate Customized QA Phantoms into Your Radiotherapy & Imaging Workflows

Upgrade your radiotherapy QA and calibration workflows with customized OEM QA tools from gKteso. Contact us to integrate tailored Solid Water (RW3) phantoms and transport units into your system validation, commissioning, and routine quality assurance processes.

- High-precision Solid Water (RW3) for reproducible QA and dosimetry results

- OEM-specific design, prototyping & scalable serial manufacturing for next-generation systems

- Water phantom transport solutions for safe handling, mobility & long-term stability

Seamless Integration

Into Imaging QA Workflows

Customized OEM QA Tools integrate directly into OEM validation, commissioning, and routine QA environments. Each system is engineered for compatibility with major LINAC, proton, and imaging platforms, ensuring precise geometric alignment and reproducible results across different detectors and workflows. Their modular design supports beam model validation, imaging calibration, and adaptive radiotherapy QA without modification to existing setups. OEMs benefit from short setup times, repeatable positioning, and simple handling in both prototype and production configurations.

Fully MDR-compliant and ISO 13485 certified, all QA tools and water phantom transport systems fit seamlessly into international QA standards, enabling consistent calibration, documentation, and system verification across global radiotherapy platforms.

Our Applications

For Advanced Imaging QA

Customized OEM QA Tools support a wide range of applications across radiotherapy and medical imaging. Each system is designed to ensure precise, reproducible results in QA, commissioning, and system validation: from prototype testing to clinical use.

Applications include:

- LINAC Commissioning: validation of beam models and dose calibration under clinical conditions

- Imaging QA (CT, MRI, PET): cross-modality calibration and distortion detection for adaptive workflows

- Adaptive Radiotherapy: consistent QA performance in real-time correction and motion management systems

- Dosimetry and Calibration: water-equivalent measurement and detector verification with RW3 material

- End-to-End QA Testing: full workflow validation from imaging to dose delivery

By combining OEM-specific design, verified materials, and global regulatory compliance, these QA systems deliver long-term reliability and seamless integration into radiotherapy and imaging workflows worldwide.

Machine-QA

Patient-QA

Imaging-QA

Laser alignment

Dosimetry

Tissue-equivalent phantoms

Learn more about our projects

Discover how gKteso’s positioning solutions are applied in advanced radiotherapy systems worldwide. From prototype integration to clinical implementation, our projects demonstrate precision engineering in real treatment environments. Learn how we collaborate with OEM partners to shape the next generation of radiotherapy technology.

Learn more about …

Seamless surface scanner integration and live motion correction during treatment.

Learn more about …

Patient Positioning Systems by gKteso: Tailored for modern radiotherapy environments.

Schedule an appointment now!

Frequently Asked Questions

Can QA phantoms be customized for OEM-specific requirements?

Yes, gKteso develops OEM-specific phantoms with tailored geometries, materials, and features – from concept and prototyping to scalable series production, ensuring seamless integration into radiotherapy and imaging systems.

How can the phantoms support SGRT integration?

The Anthropomorphic Head Phantom includes camera-recognition features such as colour markers, RFID options, and optional facial structures. This enables validation and calibration of SGRT systems, ensuring accurate patient positioning in daily workflows.

What materials are used for customized phantoms?

We primarily use high-precision Solid Water (RW3) and other radiation-hard materials such as PMMA, Carbon-infused PEEK or epoxy, offering tissue-equivalent properties, reproducibility, and long-term durability for clinical QA and research applications.

Do the MR phantoms interfere with imaging?

No. Our MR-compatible phantoms contain no ferromagnetic components and are MR conditional up to 3T. They are specifically designed to detect laser alignment errors and imaging distortions without introducing artifacts, ensuring high-quality MR images.

What is the typical lead time for customized phantoms?

Lead times vary depending on design complexity. Standard prototypes are typically available within 4-6 weeks, while serial production timelines are adapted to OEM project requirements and global delivery schedules down to 1 week for individual ion-chamber adapters.

Explore more advanced QA & patient positioning solutions for radiotherapy

RW3 Solid Water Standard Phantoms

RW3 Solid Water Standard Phantoms are the gold standard for quality assurance and calibration in radiotherapy. With tissue-equivalent density, reproducibility, and global compliance, they support OEM integration, clinical QA, and research applications.

RPS SGRT

The RPS SGRT provides image-guided precision without compromise for frameless radiotherapy treatments. It continuously monitors patient motion in real time to maintain exact positioning during irradiation. With intrafraction tracking and non-invasive setup, it ensures consistent accuracy and patient comfort throughout the procedure.

RPS HEAD

The RPS Head delivers high-precision positioning for cranial and head-and-neck radiotherapy. With integrated 6DoF motion control, it enables submillimeter correction in pitch, roll, and yaw even after the thermoplastic mask is fixed. Designed for stereotactic and image-guided workflows, it ensures stable geometry, minimizes repositioning, and supports accurate SGRT and CBCT verification throughout every treatment session.